Silicone Tubing Manufacturer: Customizing Solutions

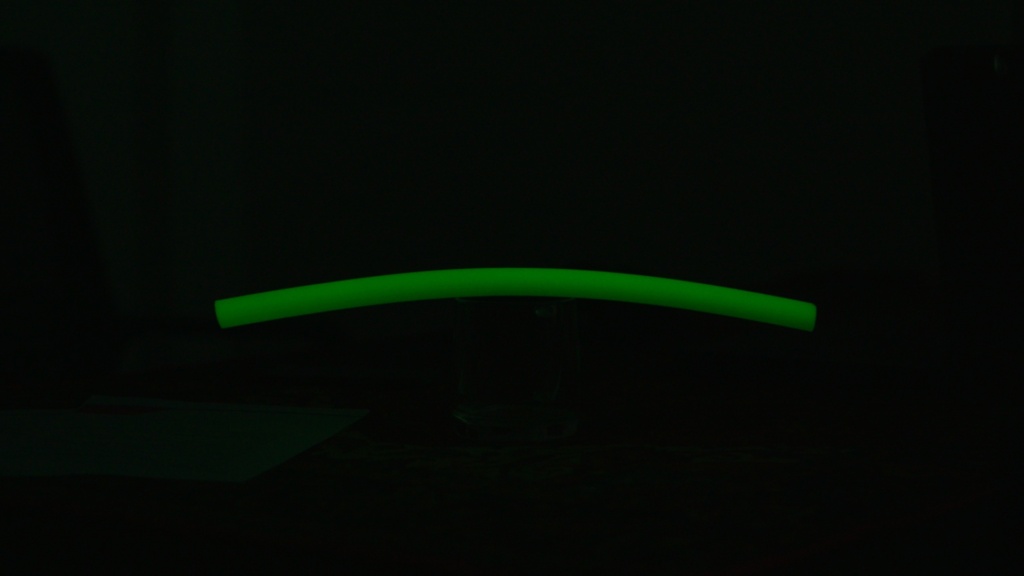

We offer manufacturing services to create silicone tubing solutions tailored to your specific needs. Our products feature a range of versatile materials, including platinum cured silicone tubing, which offers excellent high temperature resistance and weather durability. We manufacture silicone tubing using an extrusion process.

Choose from our range of customization options

Silicone tubing has several key features:

Silicone tubing is flexible and elastic, allowing for tight bends and frequent movement. Its ability to withstand stressful conditions makes it a versatile material for use in dynamic environments.

- Food grade compatibility

- Temperature range

- Durability against UV radiation

- Weather resistance

- Flexibility

- Durability

- Chemical resistance

- Elasticity

- Ability to stretch

- Bio-compatibility

- Pressure ratings, ranging from 5 psi to 200 psi

- From: Inner diameters: 0.5 mm and Wall thicknesses: 0.3 mm

What features do you need in your silicone tubing?

To ensure that we manufacture the perfect silicone tubing solution for you, please specify the following:

- Material properties:

- Do you require flexibility and elasticity?

- Are there specific temperature ranges or chemical resistances needed?

- Do you need durability against UV radiation or weathering conditions?

- Tube dimensions:

- What is your required inner diameter (ID)?

- What is your required outer diameter (OD)?

- What length of silicone tubing do you need?

- Wall thickness:

- Do you require a specific wall thickness?

- Shore hardness:

- Is there a specific Shore hardness rating needed for your application?

- Color and texture:

- Do you have a preferred color or texture for the silicone tubing?

Silicone Tube For Industry-specific applications

Which industry are you in? Choose one from the list below:

- Medical devices (e.g. catheters, syringes)

- Aerospace and defense

- Chemical processing and handling

- Food and beverage processing

- Pharmaceutical manufacturing

- Hydraulic and pneumatic systems

- Bio research or laboratory applications

Certifications:

Do you require any specific certifications for your application? Choose one or more from the list below:

- FDA, CE, or UL certification

- Compliance with industry standards (e.g. ASTM, ISO)

- Customized certifications for your specific application

See the certifications and standards we adhere to.

Quality and reliability:

What level of quality and reliability do you require?

- Do you need tight tolerances and consistent dimensions?

- Are high-quality raw materials essential?

- Should we implement robust testing and inspection procedures?

Find out who we are and what we do.

Customization options:

Do you have any additional customization requirements? Please let us know if you:

- Require custom tube dimensions or shapes

- Need specific material formulations

- Have specialized packaging or labeling requirements

Provide your specifications and we’ll create a custom solution.

Explore our silicone product manufacturing services.

Get Answers: Silicone Tubing Questions and Answers

Silicone tubing is tough and lasts a long time, especially in tough conditions. It fights against weathering, ozone, sunlight, and moisture, making it last even longer.

Yes, silicone tubing is excellent at resisting chemicals. It holds up well even with exposure, without breaking down.

Our silicone tubing has pressure ratings ranging from 5 psi to 200 psi, making it suitable for both low and high-pressure applications. But it can be customized to meet your needs.

Yes, we offer customizable silicone tubing options in custom lengths, diameters, and colors to meet the specific needs of your project.

Our silicone tubing can handle extreme temperatures, from -50°C to 250°C (-58°F to 482°F), making it suitable for both cold and hot conditions.

Yes, our silicone tubing is designed to withstand autoclaving cycles at 134°C (273°F) and can be sterilized using various methods. (It depends on silicone material you choose)

Our silicone tubing meets FDA standards and is safe for use in food processing, medical devices, and pharmaceutical applications. For medical needs we use silicone Liveo C6 and Q7.

Yes, we offer reinforced silicone tubing options strengthened with materials like fiberglass or wire, as well as specialty tubing for specific scenarios, such as high-purity applications.