Silicone Rubber Overmolding: Custom Solutions for High-Performance Applications

Silicone rubber overmolding is a versatile manufacturing process that allows for the seamless integration of various materials to create customized, durable, and functional components. By combining the unique properties of silicone with other materials such as 304 stainless steel, electronics, plastics, fabrics, and more, this technique opens up endless possibilities for innovation across multiple industries.

Key Features of Silicone Rubber Overmolding

Customization Involving Material Integration

One of the standout advantages of silicone rubber overmolding is its ability to integrate seamlessly with a wide range of materials. This process enables the creation of products that combine the flexibility and biocompatibility of silicone with the strength and durability of metals, plastics, or textiles. For instance:

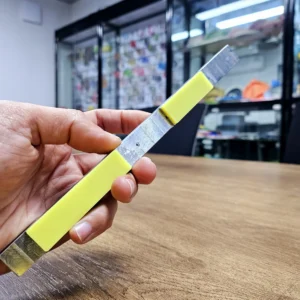

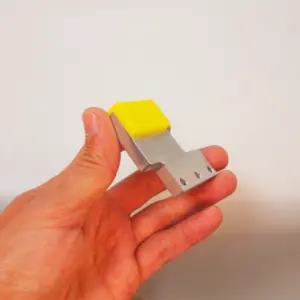

- 304 Stainless Steel: When combined with silicone, it creates a hybrid material that is both robust and aesthetically pleasing, ideal for medical devices and industrial tools.

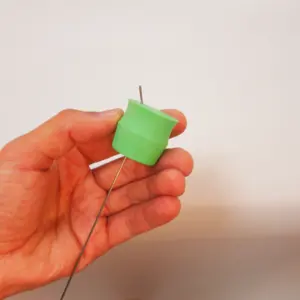

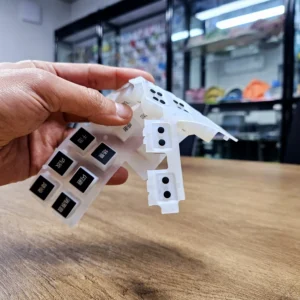

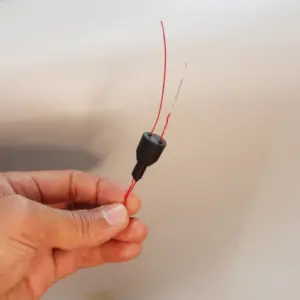

- Electronics: Silicone overmolding can protect sensitive electronic components while offering flexibility and resistance to environmental factors.

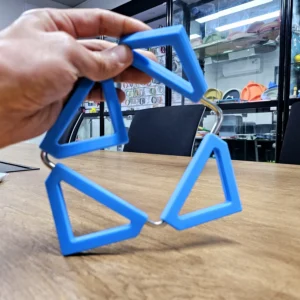

- Plastics and Fabrics: These materials can be integrated to enhance grip, comfort, or insulation in products such as handles, sports equipment, and furniture.

Biocompatibility for Medical Devices

Silicone’s inherent biocompatibility makes it an excellent choice for medical applications. Specifically, silicone overmolding is widely used to create components such as:

- Stoppers: Used in pharmaceutical packaging to ensure airtight sealing while maintaining sterility.

- Surgical Devices: Components like grips, handles, and instrument tips that require both precision and biocompatibility.

Applications of Silicone Rubber Overmolding

Silicone rubber overmolding finds applications across various industries due to its adaptability and performance benefits. Here are some key areas where it is commonly utilized:

- Non-slip, ergonomic handles for tools like wrenches, screwdrivers, and pliers

- Enhanced comfort and durability in golf grips, tennis rackets, and cycling handlebars

- Protective cases for smartphones, tablets, and laptops

- Customized biocompatible components for medical equipment

- Automotive parts including steering wheel covers, gearshift knobs, and dashboard trim

- Non-slip surfaces for kitchen utensils and bathroom accessories

- Lightweight and durable aerospace components for aircraft controls and cockpit trim

- Ergonomic industrial tools such as pliers and wrenches to reduce user fatigue

- Marine products offering durability in harsh environments, like boat handles and deck hardware

- Stylish and comfortable furniture components, including chair arms, table legs, and cabinet handles

- Improved performance and grip in sports equipment like golf grips, tennis rackets, and cycling handlebars

Choosing the Right Partner for Silicone Rubber Overmolding

Selecting the right partner is crucial for ensuring high-quality silicone rubber overmolding solutions. Consider a partner with:

- Years of Experience: A proven track record in delivering customized solutions.

- Tracable Materials: Assurance of material traceability and quality control.

- Certifications: Compliance with industry standards and regulations.

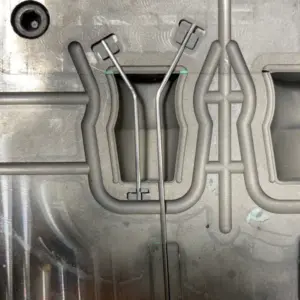

- In-House CNC for Tool Creating: Capabilities to design and produce precise molds in-house.

- Prototype Testing Services: The ability to test and refine prototypes before full-scale production.

Contact us

Let’s explore how we can collaborate to create innovative solutions tailored to your needs. Contact us today to get started.