Compression Molding Silicone Manufacturing Services

We design our compression molding silicone with a focus on functionality, precision, and affordability to meet diverse industry needs. Our products deliver high performance while adhering to strict global quality standards. Contact us today for expert guidance and fast quoting.

- DFM Design Review

- Rapid Prototyping

- High & Low-Volume Production

- Tolerance: ±0.2/0.3 mm

- In-House CNC Mold Machining

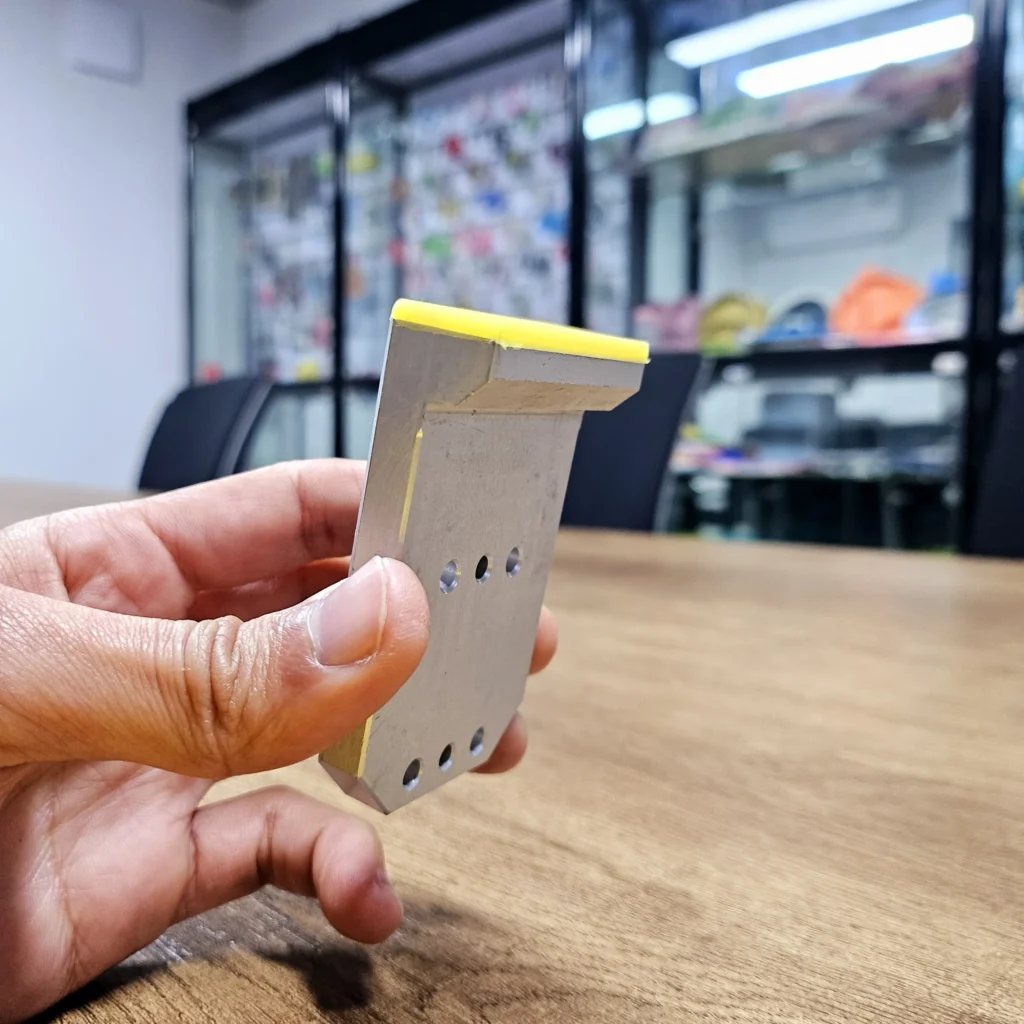

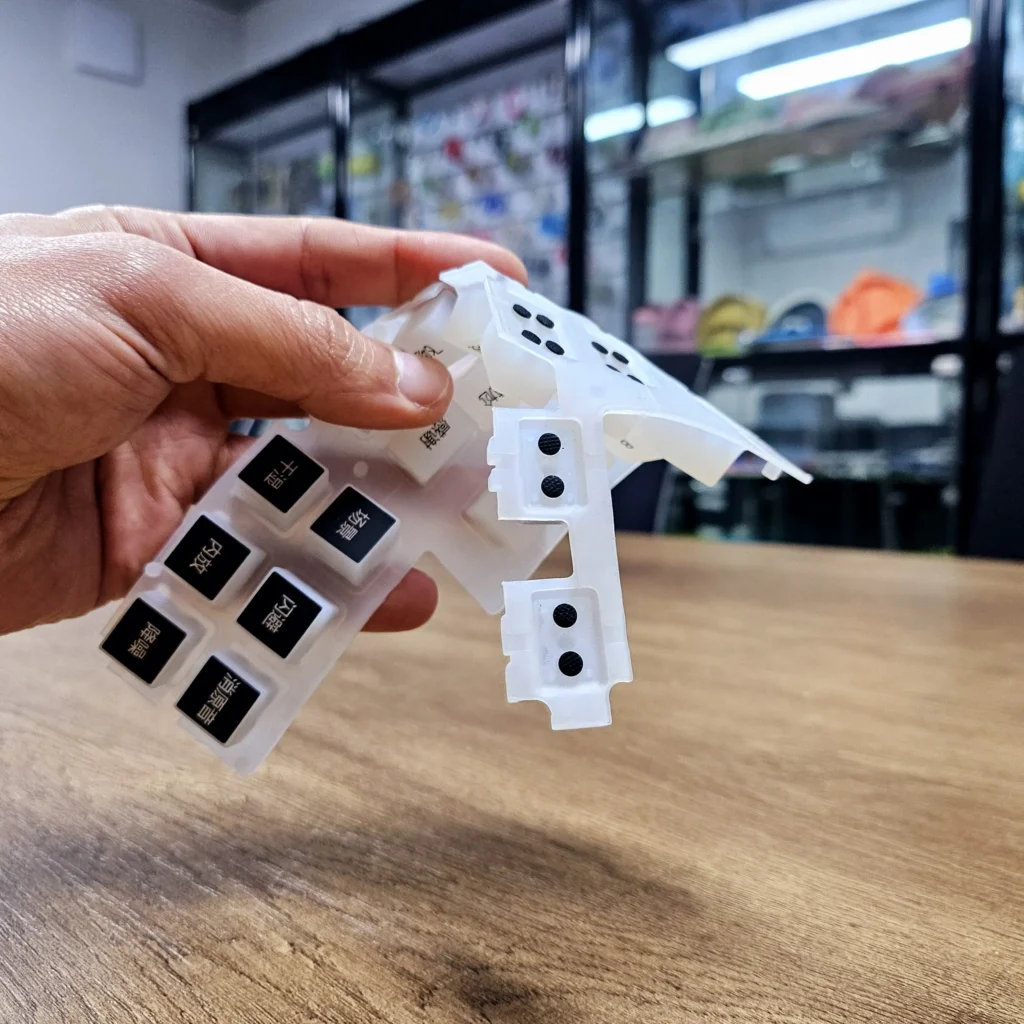

- Silicone Overmolding

What is Silicone Compression Molding?

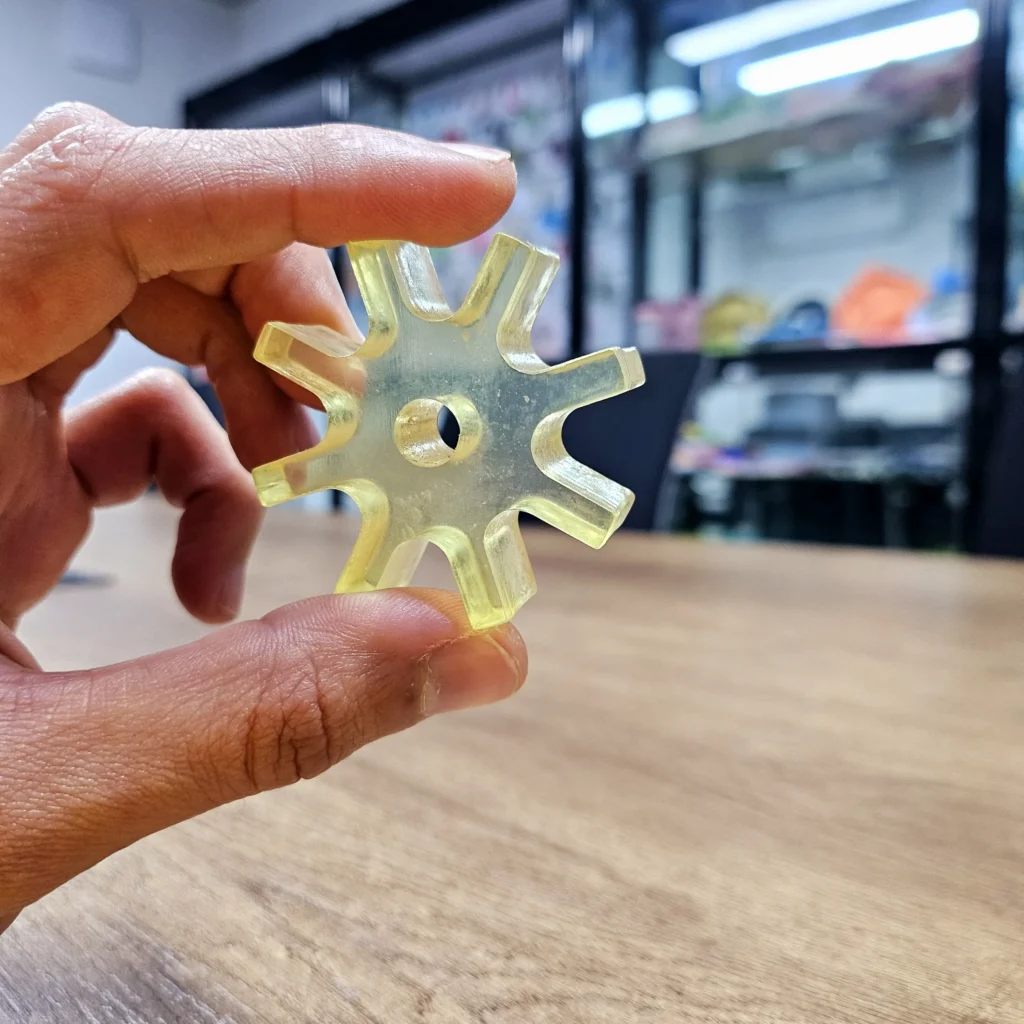

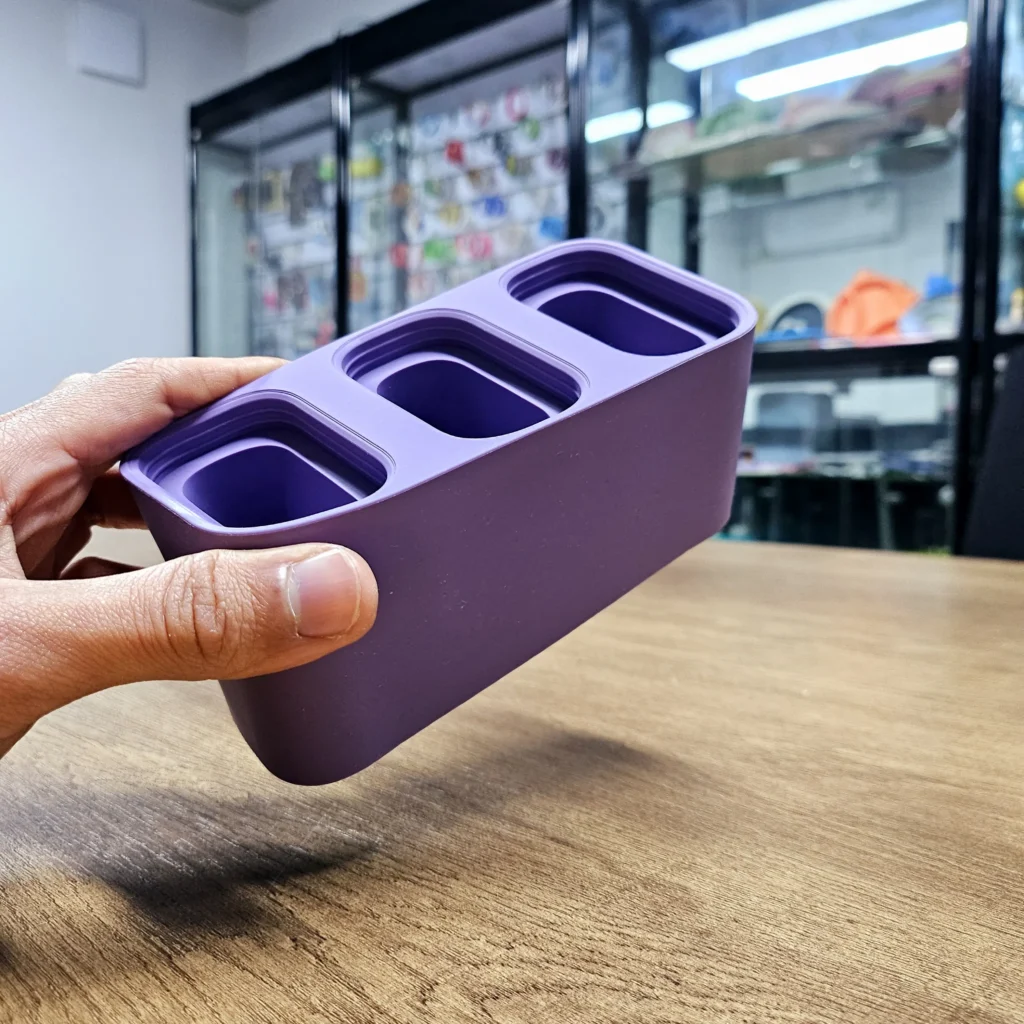

Silicone compression molding is a cost-effective and reliable process for manufacturing precision rubber parts. It ensures high detail, minimal stress, and excellent durability, making it ideal for industries such as lab devices, automotive, consumer products, and more. Complete Compression Molding Guide – Learn the full process.

How Does It Work?

Using your design, we create a two-part mold consisting of a base plate and an elevated profile. Silicone is placed on the base plate, then compressed under heat and pressure until it fully conforms to the mold. This ensures tight tolerances, repeatability, and high-quality components, making it ideal for gaskets, seals, lab equipment, and more.

Compression Molding Applications

Silicone compression molding is widely used across various industries, including:

- Automotive: Gaskets, seals, and other critical rubber components.

- Lab Devices: Biocompatible precision parts such as bungs, sleeves, and other silicone components.

- Electronics: Heat-resistant and flexible parts like LED light gaskets, tubing, and rubber sheets.

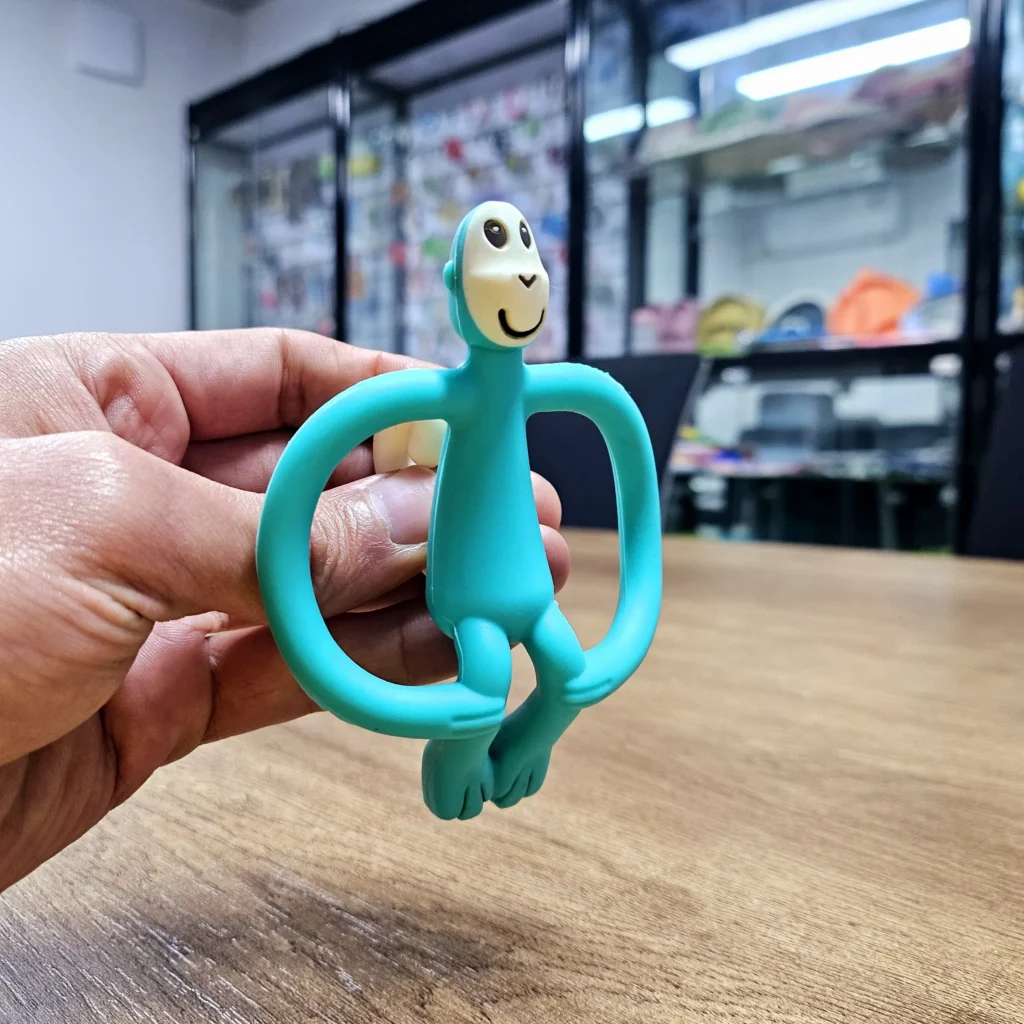

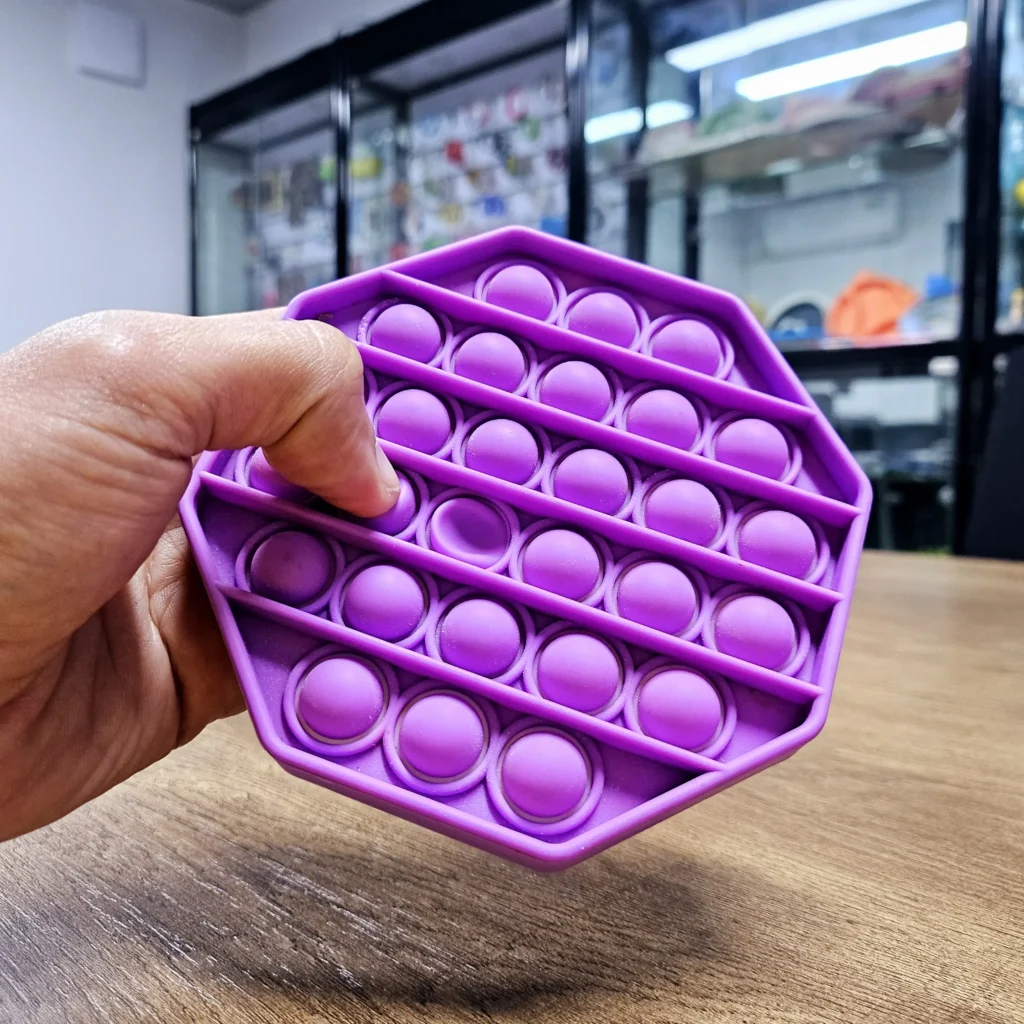

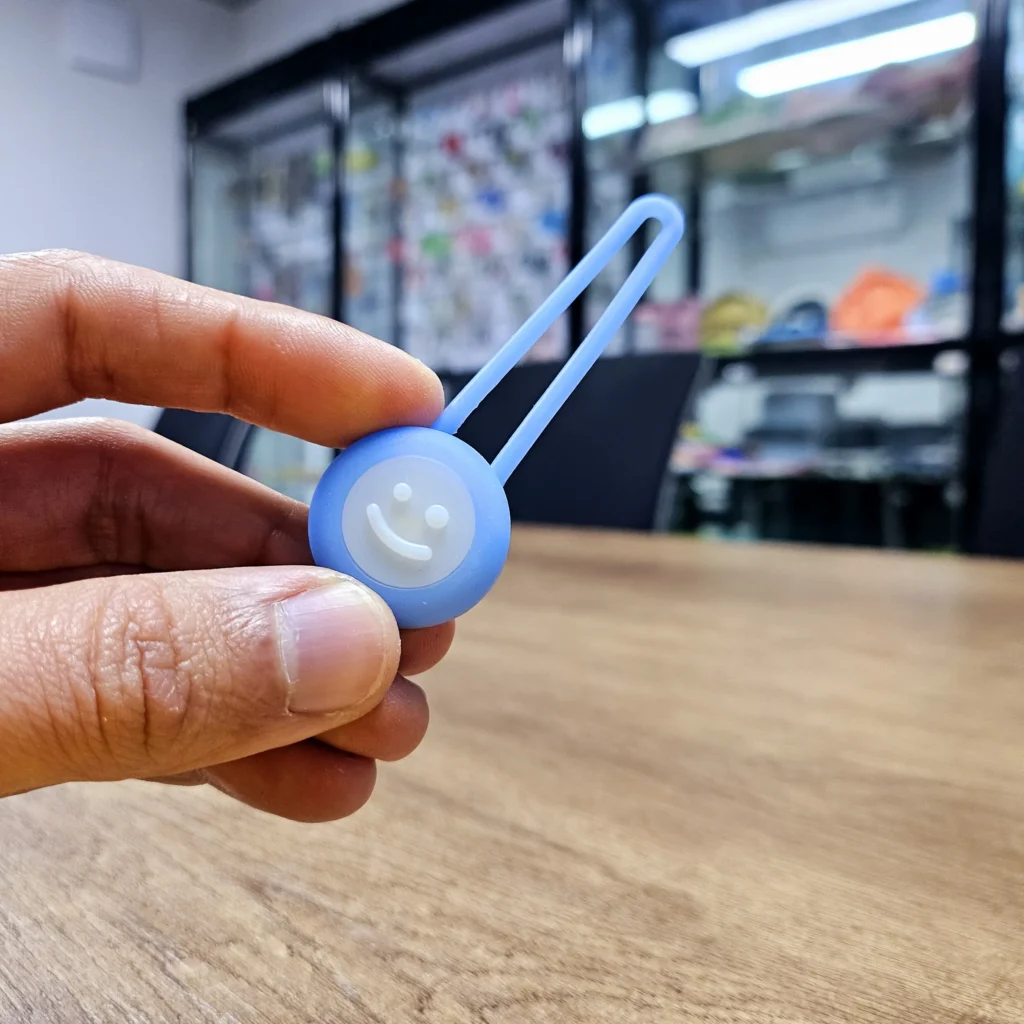

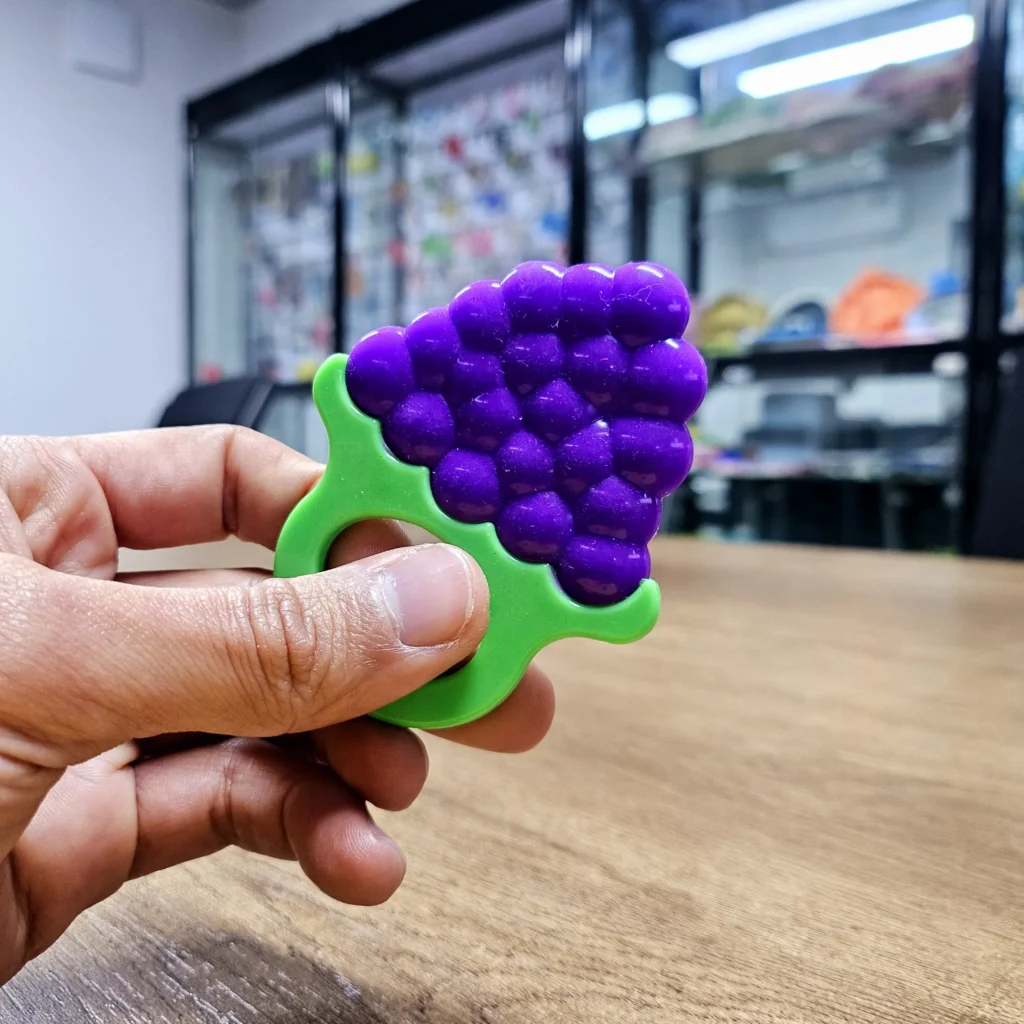

- Consumer Goods: Smartphone cases, headphone silicone parts, kitchen utensils, and more.

Request Your Custom Quote Today

Can you assist with making my design manufacturable or help with the initial design?

Yes, we can review your design to ensure it is suitable for manufacturing and provide design assistance if needed.

What are your production volume capacities and lead times?

Production capacity depends on product complexity and mold quantity. For example, a single 16-cavity mold can produce up to 7,000 pieces per day with two shifts.

Can you provide a detailed cost estimate?

We offer pricing based on your specific design requirements. This includes mold costs, production fees, secondary operations, and any additional expenses such as overmolding materials or shipping.

Can you provide timelines and delivery dates for orders?

Our typical lead time for mass production molds ranges from 10 to 15 days, while prototypes are typically ready within 3 to 5 days of ordering.