Custom Silicone Rubber Cord Service

We provide custom made silicone rubber cords designed to meet specific requirements for various industries and applications. Our silicone cord service involves designing, developing, and producing quality cords using various silicone materials and manufacturing techniques.

Our Custom Silicone Cord Development Process

We follow a structured process to ensure that every custom silicone cord project meets our quality and reliability standards. Our approach involves working closely with customers to understand their specific needs and requirements.

Regulatory Compliance

We operate within the boundaries of relevant regulations and industry standards, ensuring that our custom silicone cord products meet specific requirements for safety and performance. Our compliance includes:

- ISO 10993: Biological Evaluation of Medical Devices

- USP Class VI: Biological Reactivity Tests, In Vivo

- IEC 62321 Series: Determination of Certain Substances in Electrotechnical Products

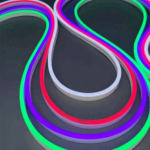

Light Emitting Silicone Rubber Cord

Silicone rubber cord can also be formulated to emit light, making it suitable for various applications where illumination is required. These light emitting silicone rubber cords are often used in:

- Glowing seals and gaskets: Bioluminescent or photoluminescent properties can be incorporated into silicone rubber cord to create glowing seals and gaskets that can help indicate leakage or damage.

- Illuminated tubing and hoses: Light emitting silicone rubber cord can be used to create illuminated tubing and hoses for various applications, such as medical devices, industrial equipment, or even fashion accessories.

- Glow-in-the-dark components: Silicone rubber cord with glow-in-the-dark properties can be used in components like buttons, switches, or other interactive devices that require visibility in low light conditions.

Applications of Our Silicone Rubber Cords

With the use of silicone rubber cord, various materials and features can be manufactured, depending on the specific requirements of the application.

- Custom shapes and sizes: Silicone rubber cord can be cut to custom lengths and diameters to fit specific applications.

- Heat resistant components: Such as heat shields, thermal insulation, or high temperature seals, can be manufactured using silicone rubber cord.

- Chemical resistant parts: Chemical resistant parts, like chemical processing equipment, laboratory containers, or pharmaceutical manufacturing components, can be made with silicone rubber cord.

- Biocompatible implants: Biocompatible implants, such as surgical devices, medical instruments, or implantable devices, can be created using silicone rubber cord.

- High temperature wire harnesses: High temperature wire harnesses for aerospace, industrial, or other applications where high temperatures are involved can be manufactured with silicone rubber cord.

- Custom seals and gaskets: Custom seals and gaskets for various industries and applications, such as food processing, pharmaceutical manufacturing, or chemical processing, can be made using silicone rubber cord.

- High vacuum components: High vacuum components, like vacuum chambers, space exploration equipment, or other applications requiring high vacuum conditions, can utilize silicone rubber cord.

- Marine equipment parts: Marine equipment parts, such as boat propellers, water jackets, or other underwater components, can be manufactured with silicone rubber cord to resist saltwater corrosion.

- Custom tubing and hoses: Custom tubing and hoses for various industries and applications, like aerospace, industrial, or medical devices, can be made using silicone rubber cord.

- Adhesive-backed materials: Adhesive-backed materials, such as pre-coated silicone rubber cord, can be used for easy bonding to other materials in various applications.