Silicone Products Manufacturing in China

We are pleased to partner with every client across the globe to bring quality silicone products for various industries such as automotive, aerospace, and consumer goods. We are based in China and are committed to providing exceptional products and services.

What Types of Silicone Products Do You Manufacture?

We manufacture a wide variety of silicone products, each with its own unique production method. Some products can be produced in multiple ways, and we will discuss the best production method to meet your specific needs. Factors such as budgeting, design complexity, and production lead time will be considered to ensure the optimal choice.

Below is a list of production methods for custom silicone products

Custom silicone products have multiple manufacturing options available, mainly restricted by design considerations.

1. Silicone Compression Molding:

Silicone Compression Molding: Best suited for large quantities with uniform thickness.

Structural Parts

- Gaskets & Seals

- Housing & Enclosures

- Shielding & Dampeners

- Mounting Feet & Inserts

- Structural Components & Frameworks

Electrical & Electronic Components

- Electrical Insulators & Cables

- Capacitor & Sensor Components

- EMI/RFI Shielding Materials

- Protective Covers & Enclosures

- Electronic Hardware Components

Medical & Healthcare Products

- Surgical Instruments & Devices

- Patient Care & Diagnostic Equipment

- Disposable Medical Products

- Pharmaceutical Packaging & Components

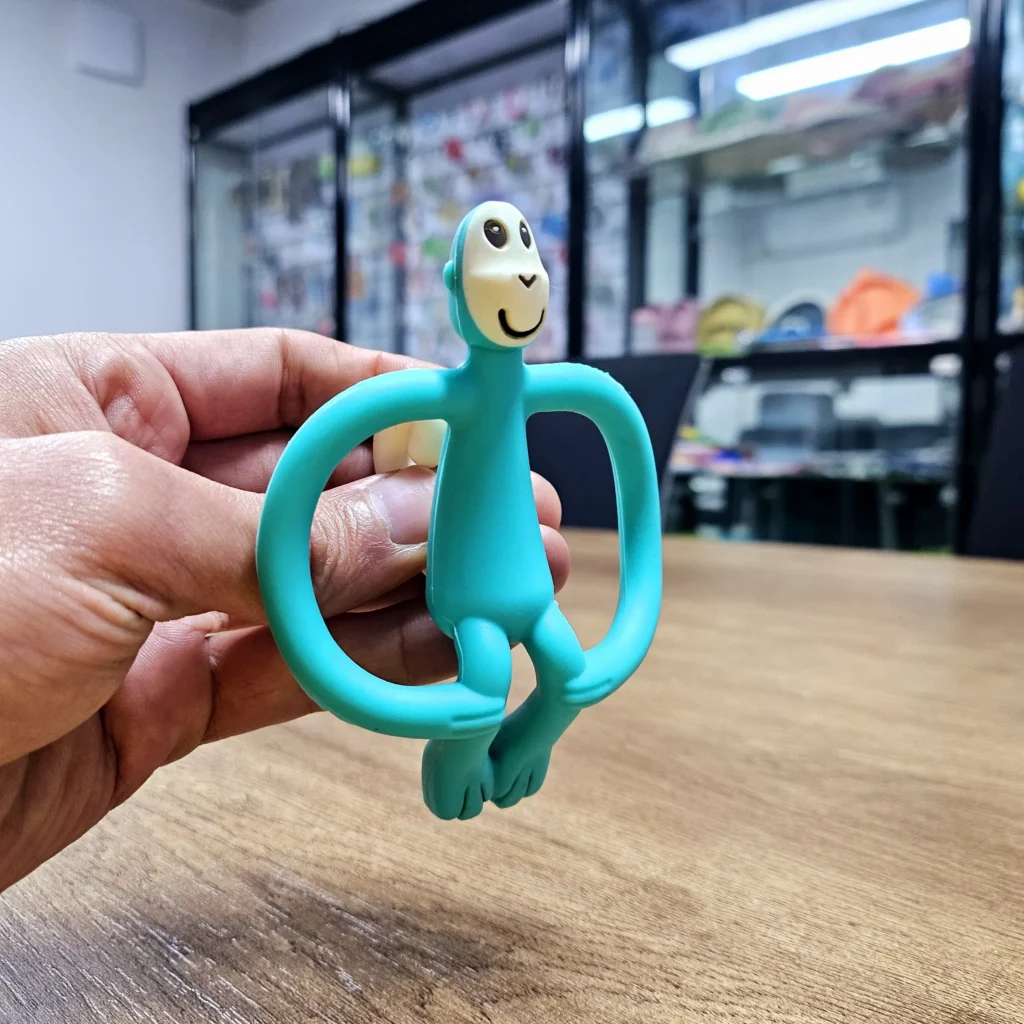

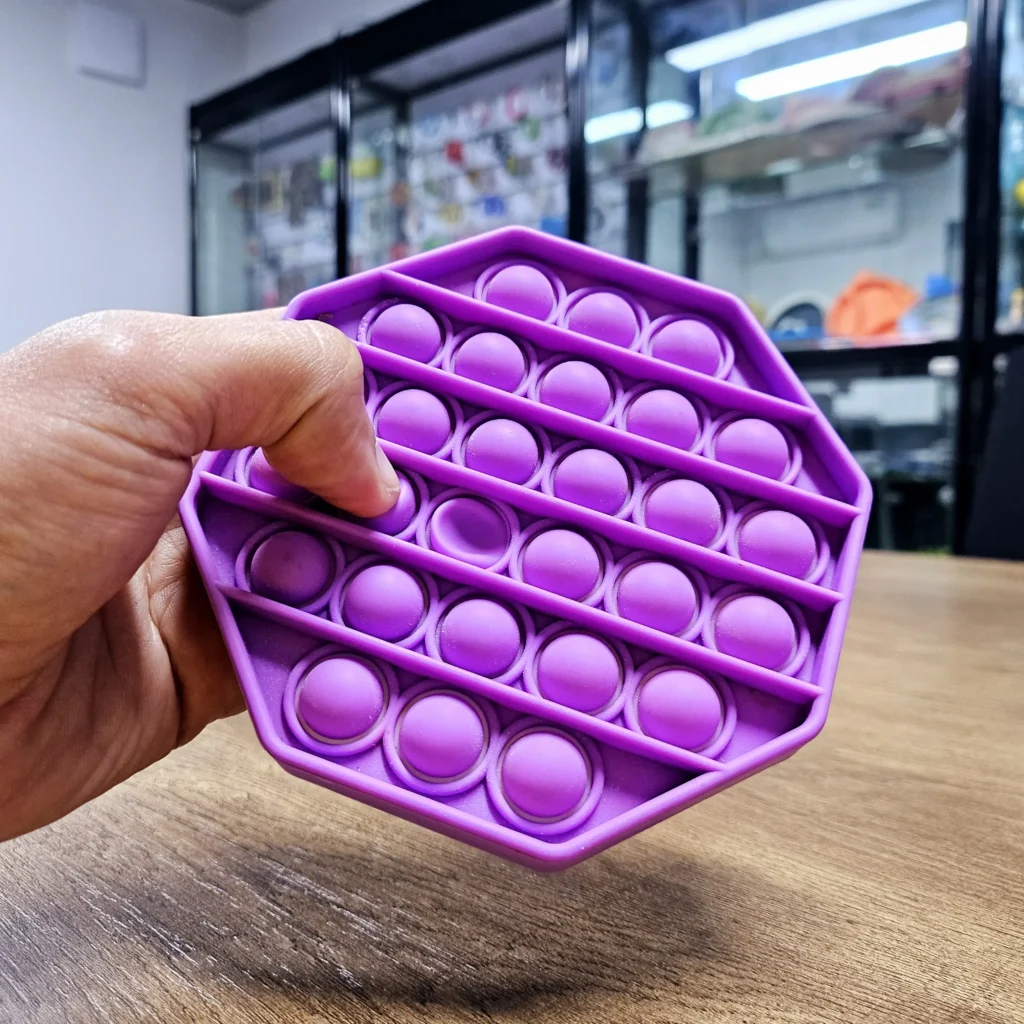

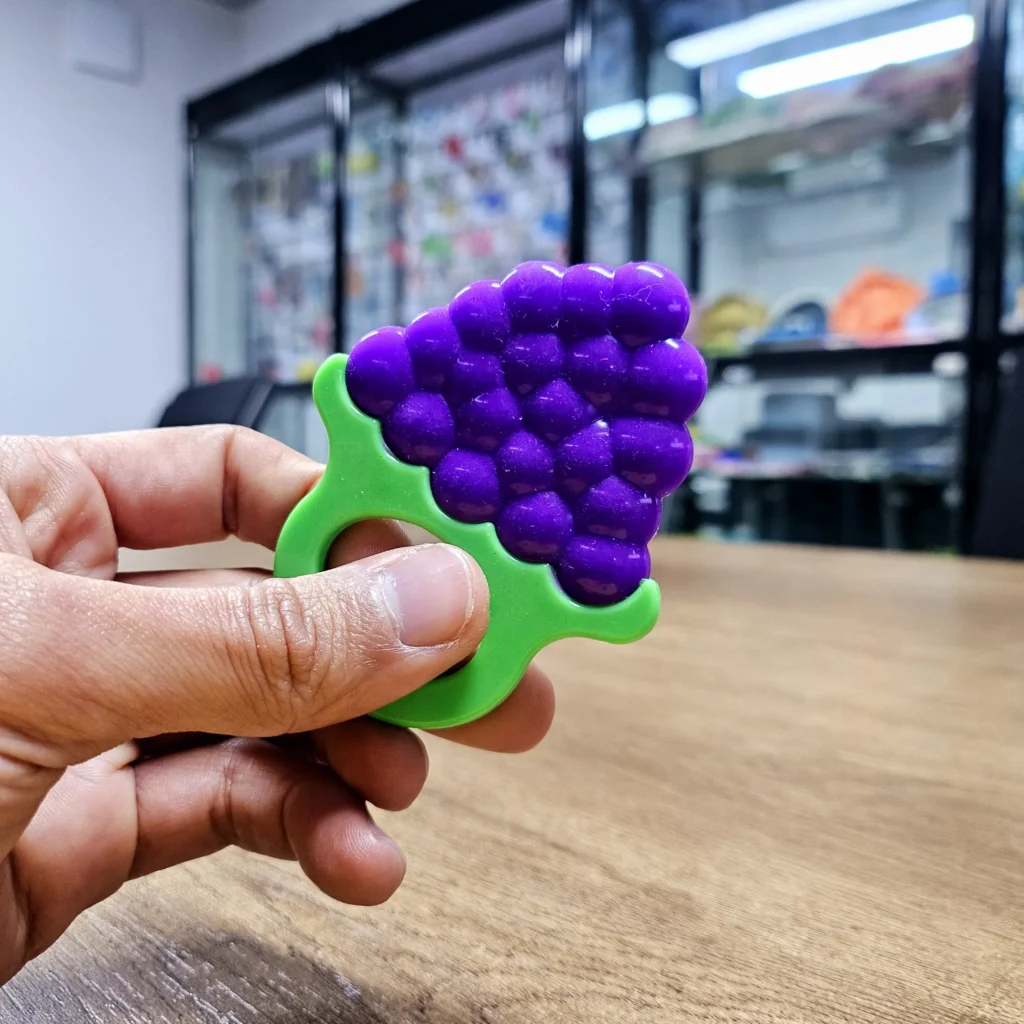

Consumer Products

- Silicone Toys & Games

- Kitchen & Food Tools

- Sporting & Fitness Products

- Cosmetic & Personal Care Products

- Fashion & Jewelry Accessories

Custom Moldings for OEM and ODM Products

- Automotive Components & Hardware

- Aerospace & Defense Components

- Industrial Tools & Machinery Parts

- Protective Covers & Seals for Industrial Applications

2. Silicone Overmolding:

Silicone Overmolding: Cost-effective method for adding multiple components or finishes to a single part.

Medical & Healthcare Products

- Disposable Medical Devices & Tools

- Patient Monitoring & Diagnostic Equipment

- Pharmaceutical Packaging & Components

- Implant Components & Surgical Instruments

Electrical & Electronic Components

- Protective Covers for Electronic Devices

- EMI/RFI Shielding Materials

- Cable & Wire Components

- Electrical Housing & Enclosures

Consumer Products

- Sporting & Fitness Products

- Kitchen & Food Tools

- Cosmetic & Personal Care Products

- Fashion & Jewelry Accessories

Industrial & Manufacturing Components

- Tools & Machinery Components

- Protective Covers & Seals

- Custom Overmolded Components for OEM Products

- Automotive Components & Hardware

Additional Custom Silicone Products

- Silicone Bung or Stopper with 304 Needle for Lab-based Industry

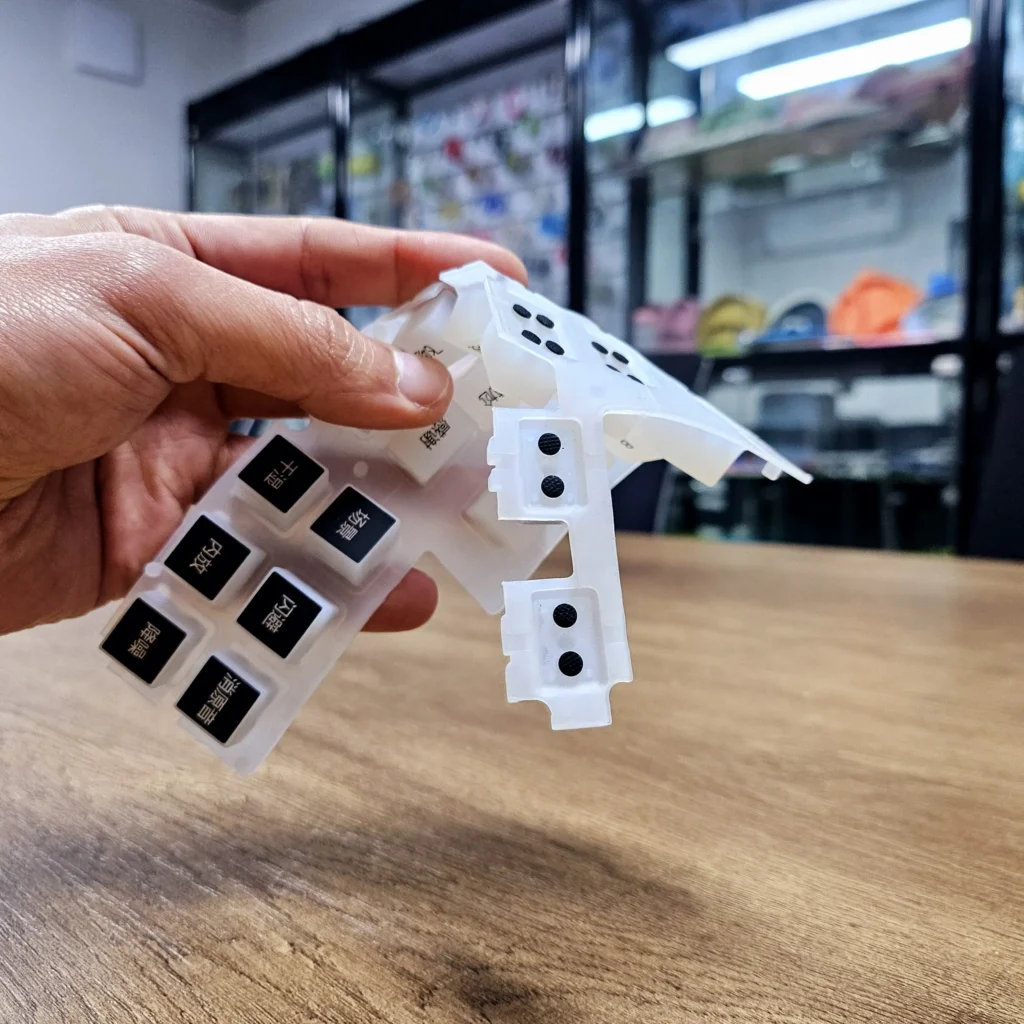

- Silicone PCBA Board Overmolding for Protection & Opaque Color

- Silicone Keycaps & Inserts for Electronic Devices

- Medical-Grade Silicone Components for Healthcare Applications

3. Silicone Extrusion Molding:

Silicone Extrusion Molding: Perfect for creating long, thin products like LED sleeves by extruding material through a die.

Tubing & Cables

- Medical Tubing & Catheters

- Hydraulic & Pneumatic Tubing

- Cable Sheathing & Protective Covers

- Industrial & Agricultural Tubing

Profiles & Shapes

- Extrusion Shapes for Mechanical & Electrical Applications

- Architectural & Structural Profiles

- Profiles for Building & Construction

- Custom-designed Silicone Extrusions

Functional Components

- Gaskets & Seals

- Hose & Pipe Fittings

- Strainers & Filters

- Profiles with Integrated Features & Functions

Consumer Products

- Silicone Straws & Water Bottles

- Silicone Food Storage & Preservation Products

- Toy & Sporting Goods

- Fashion & Jewelry Accessories

Industrial & Manufacturing Components

- Custom Silicone Extrusions for OEM Products

- Automotive Components & Hardware

- Aerospace & Defense Components

- Electrical & Electronic Components

4. Silicone Injection Molding:

Silicone Injection Molding: Ideal for high-volume production with complex designs.

Structural Parts

- Housing & Enclosures

- Medical Implant Components

- Automotive Parts & Components

- Aerospace & Defense Components

Electrical & Electronic Components

- Electrical Enclosures & Components

- Capacitor & Sensor Components

- Protective Covers & Overmolded Components

Medical & Healthcare Products

- Medical Devices & Implant Components

- Diagnostic & Analytical Equipment

- Pharmaceutical Packaging & Components

Consumer Products

- Kitchen & Food Tools

- Sporting & Fitness Products

- Toys & Games

- Cosmetic & Personal Care Products

- Baby Products

5. Silicone Dispensing Molding

Silicone Dispensing Molding: Creates complex shapes and thin-walled parts with high accuracy and multiple colors.

Custom Jewelry & Accessories

- Focal Beads – Custom shapes, vibrant colors, and personalized designs.

- Pendant Charms – Ideal for necklaces or bracelets.

- Earrings – Unique, lightweight, and colorful designs.

- Hair Ties and Clips – Soft, durable, and stylish silicone accents.

- Keychain Charms – Fun, customizable, and flexible designs.

Kitchenware

- Baking Molds – Custom shapes for cakes, cookies, and candies.

- Coasters – Heat-resistant and customizable designs.

- Utensil Handles – Comfortable, ergonomic grips in various colors.

- Jar Openers – Textured, slip-resistant designs.

- Ice Cube Trays – Fun shapes and multi-color sections.

Tech Accessories

- Cable Management Clips – Flexible, colorful options for organizing cords.

- Phone Cases – Soft-touch, durable, and shock-absorbent.

- Earphone Holders – Compact, portable, and non-slip.

- Laptop Sleeves – Protective silicone cases with stylish patterns.

Home & Lifestyle Products

- Silicone Grips for Furniture – Anti-slip pads for chairs and tables.

- Decorative Coasters – Custom-shaped and multi-colored designs.

- Silicone Straws – Reusable, eco-friendly, and colorful.

- Lightweight Plant Pots – Flexible, waterproof, and unique designs.

- Suction Hooks – Functional and easy to use.

Custom Projects

- Focal Beads – Custom shapes, vibrant colors, and personalized designs.

- Pendant Charms – Ideal for necklaces or bracelets.

- Earrings – Unique, lightweight, and colorful designs.

- Hair Ties and Clips – Soft, durable, and stylish silicone accents.

- Keychain Charms – Fun, customizable, and flexible designs.

- Baking Molds – Custom shapes for cakes, cookies, and candies.

- Coasters – Heat-resistant and customizable designs.

- Utensil Handles – Comfortable, ergonomic grips in various colors.

- Jar Openers – Textured, slip-resistant designs.

- Ice Cube Trays – Fun shapes and multi-color sections.

- Cable Management Clips – Flexible, colorful options for organizing cords.

- Phone Cases – Soft-touch, durable, and shock-absorbent.

- Earphone Holders – Compact, portable, and non-slip.

- Laptop Sleeves – Protective silicone cases with stylish patterns.

- Silicone Grips for Furniture – Anti-slip pads for chairs and tables.

- Decorative Coasters – Custom-shaped and multi-colored designs.

- Silicone Straws – Reusable, eco-friendly, and colorful.

- Lightweight Plant Pots – Flexible, waterproof, and unique designs.

- Suction Hooks – Functional and easy to use.

- Promotional Items – Branded keychains, wristbands, or coasters.

- DIY Craft Kits – Custom silicone molds for at-home projects.

6. Silicone Die cutting:

Silicone Die Cutting: A versatile process for creating complex shapes and designs with precise control over material flow.

Precise Cut Shapes

- Complex shapes and geometries for various applications

- Precise cuts for gaskets, seals, and other sealing components

- Precise die cutting for electronic components and medical devices

Label & Identification Products

- Custom-shaped silicone labels for branding and identification purposes

- Medical ID tags and labels for patient safety and tracking

- Security seals and tamper indicators for authentication and protection

Protective Covers

- Custom-cut silicone covers for electronic devices, medical equipment, and other sensitive items

- Protective covers for industrial parts and components

- Food-grade silicone covers for kitchenware and utensils

Custom Components

- Silicone components for assemblies and OEM products

- Aerospace & Defense components

- Automotive components

Specialized Products

- Silicone gaskets and seals for various applications

- Silicone precision parts for medical devices and electronics

- Silicone components for artistic and decorative applications

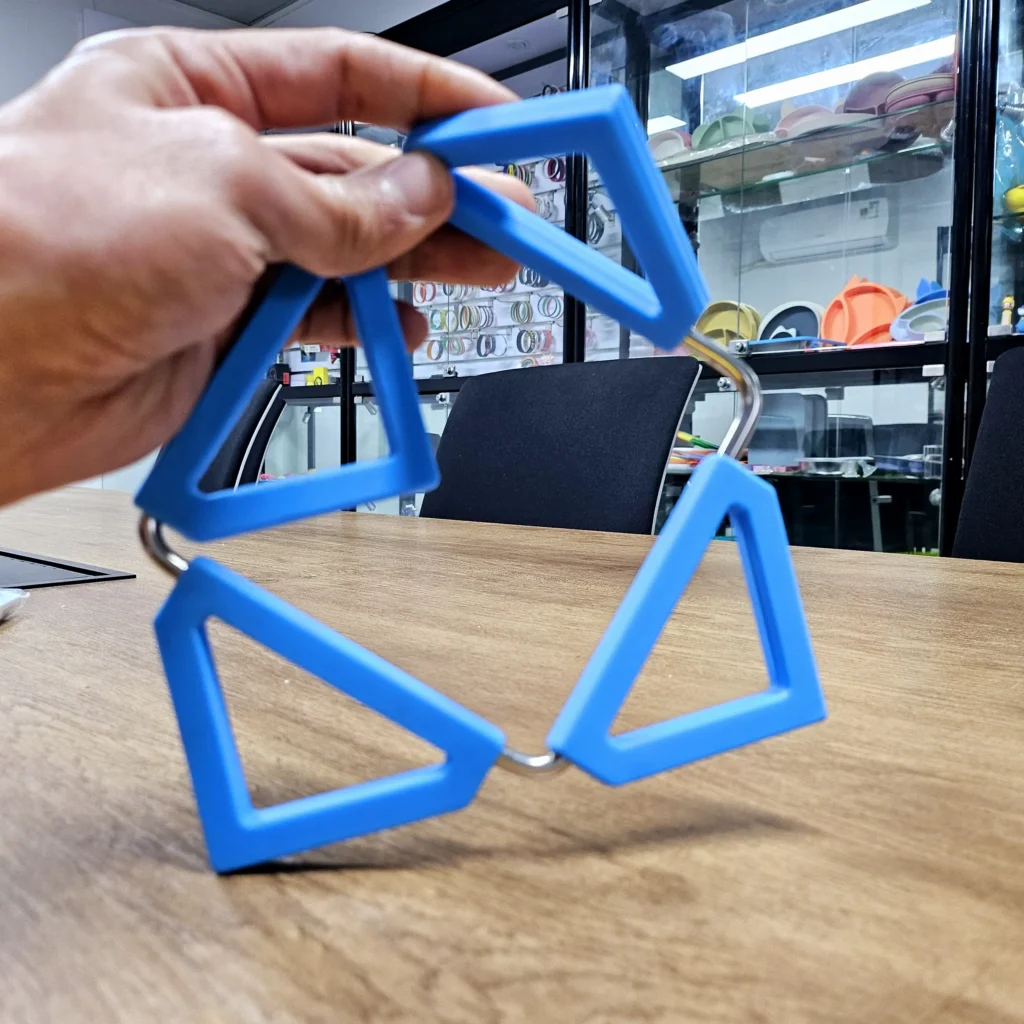

7. Silicone Filament Winding

Silicone Filament Winding: Specialized method for producing unique, high-strength core components using Aramid fabric or stainless steel springs.

Aerospace & Defense

- Composite structures for aircraft

- Protective barriers

- Thermal management systems for high-performance applications

Medical Devices

- Bone fixation devices

- Diagnostic and therapeutic tools

Automotive

- Lightweight and durable structural components

- Fuel and emission control systems

- Advanced thermal management systems

Energy & Power

- High-performance electrical insulation materials

- Energy storage devices and components

- Smart grid and renewable energy technologies

Consumer Products

- Sporting and fitness equipment

- Protective gear for outdoor activities

- Luxury and fashion accessories

Industrial & Manufacturing

- Lightweight and corrosion-resistant structural components

- Advanced composite materials for various industries

- High-performance thermal and electrical insulation materials

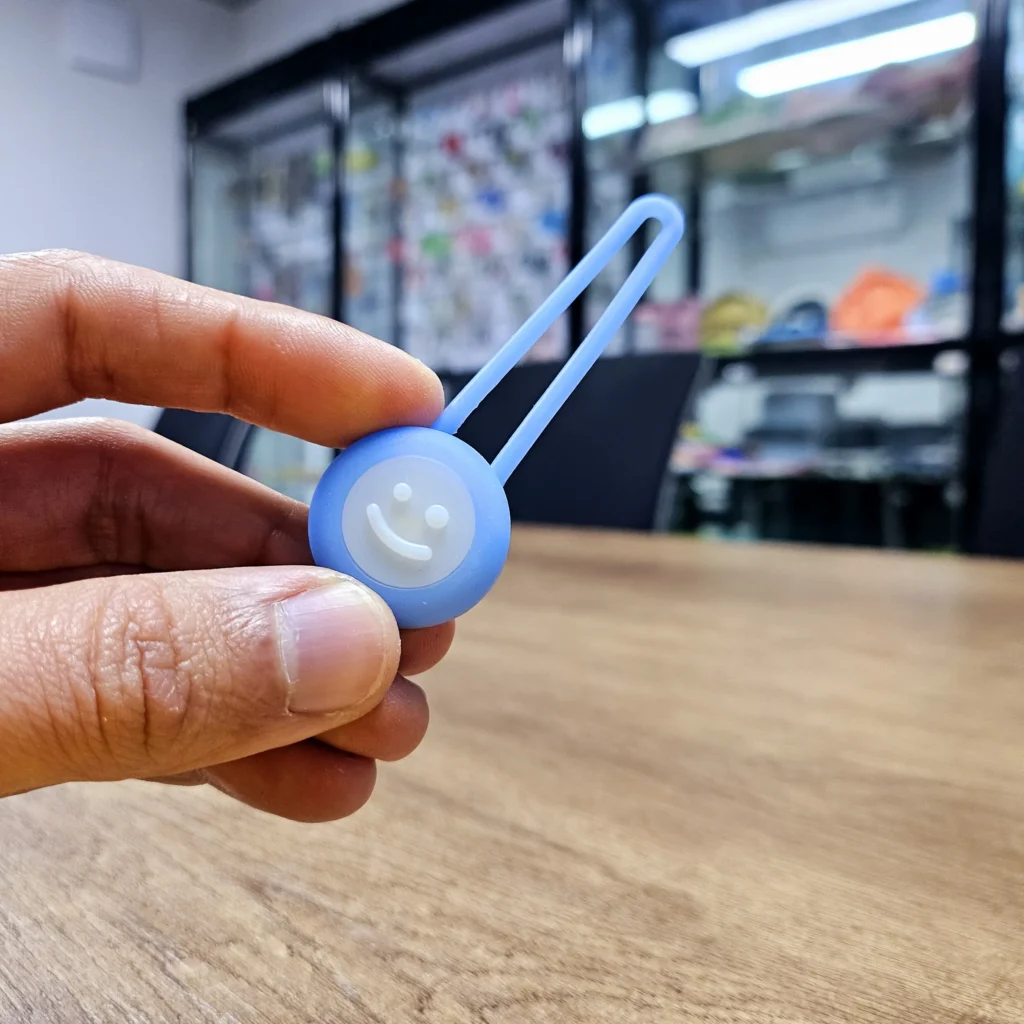

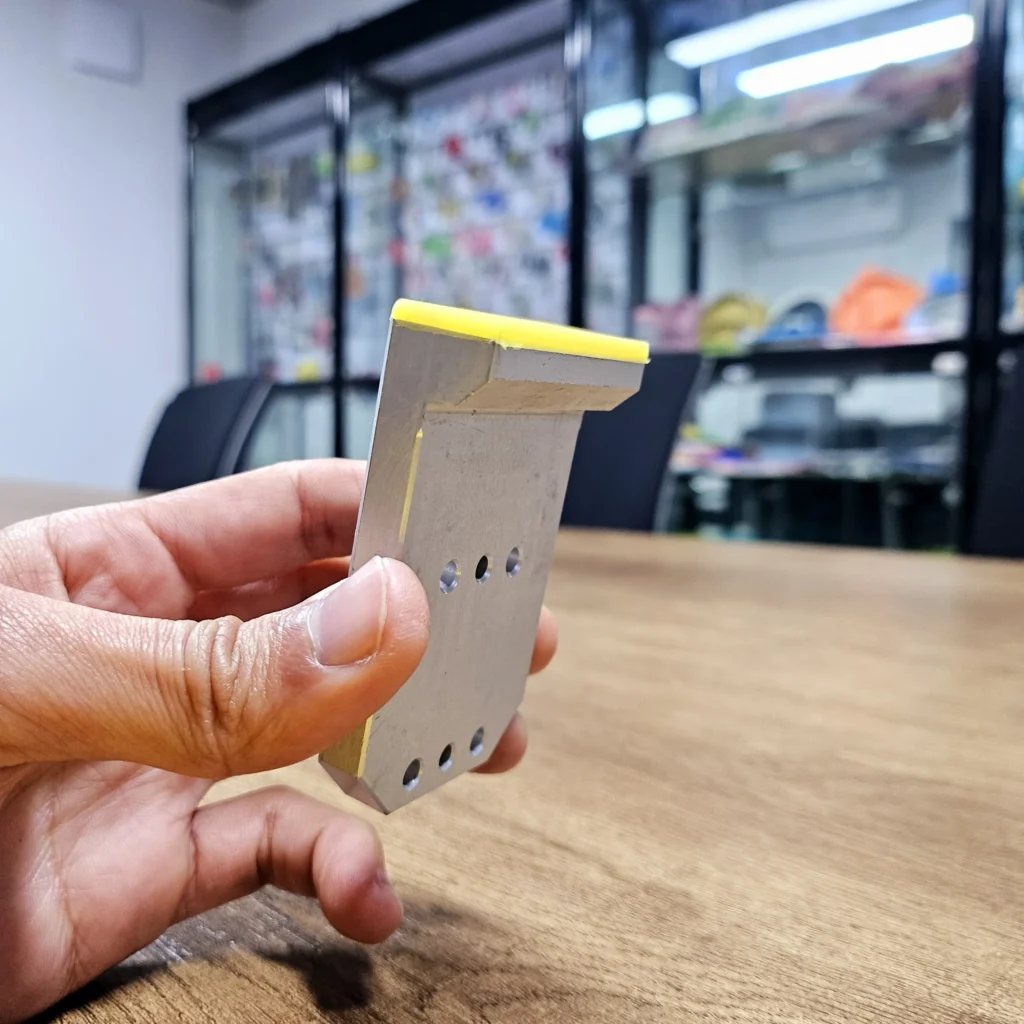

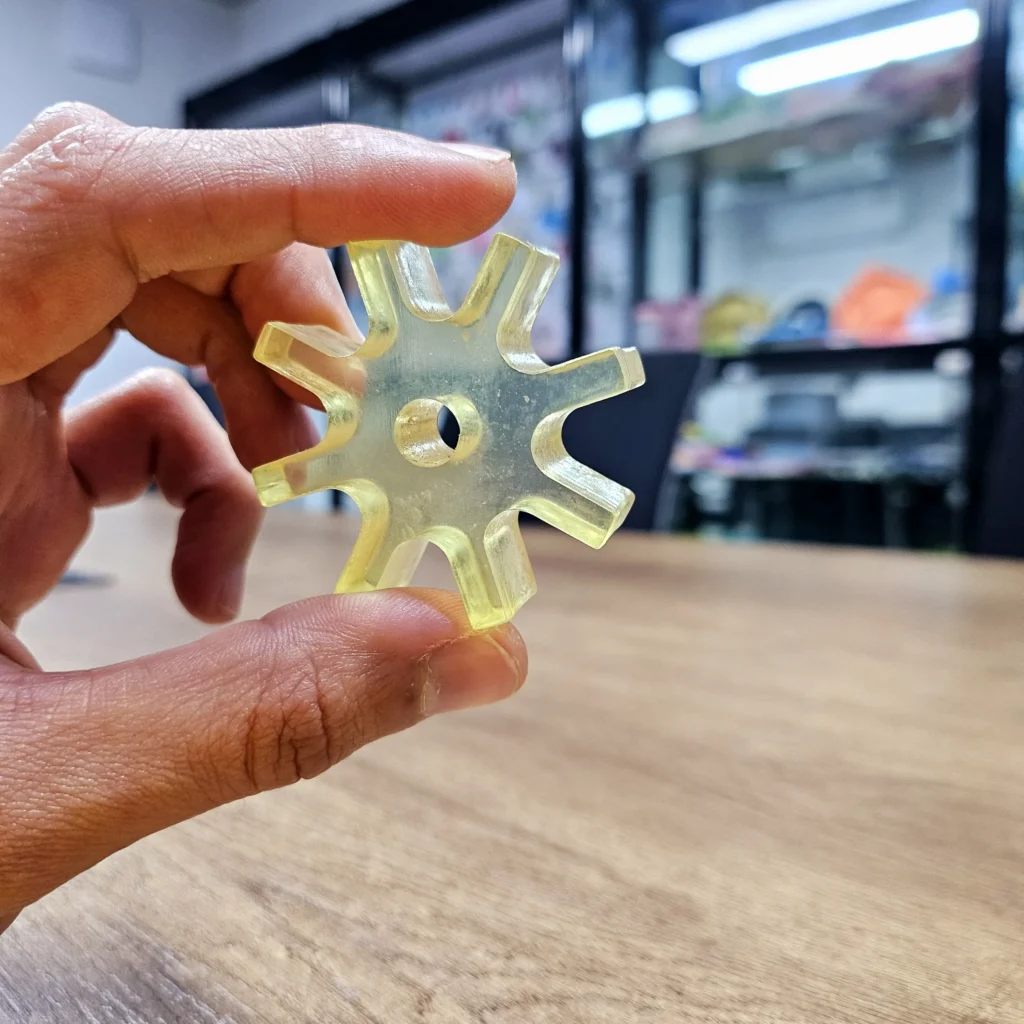

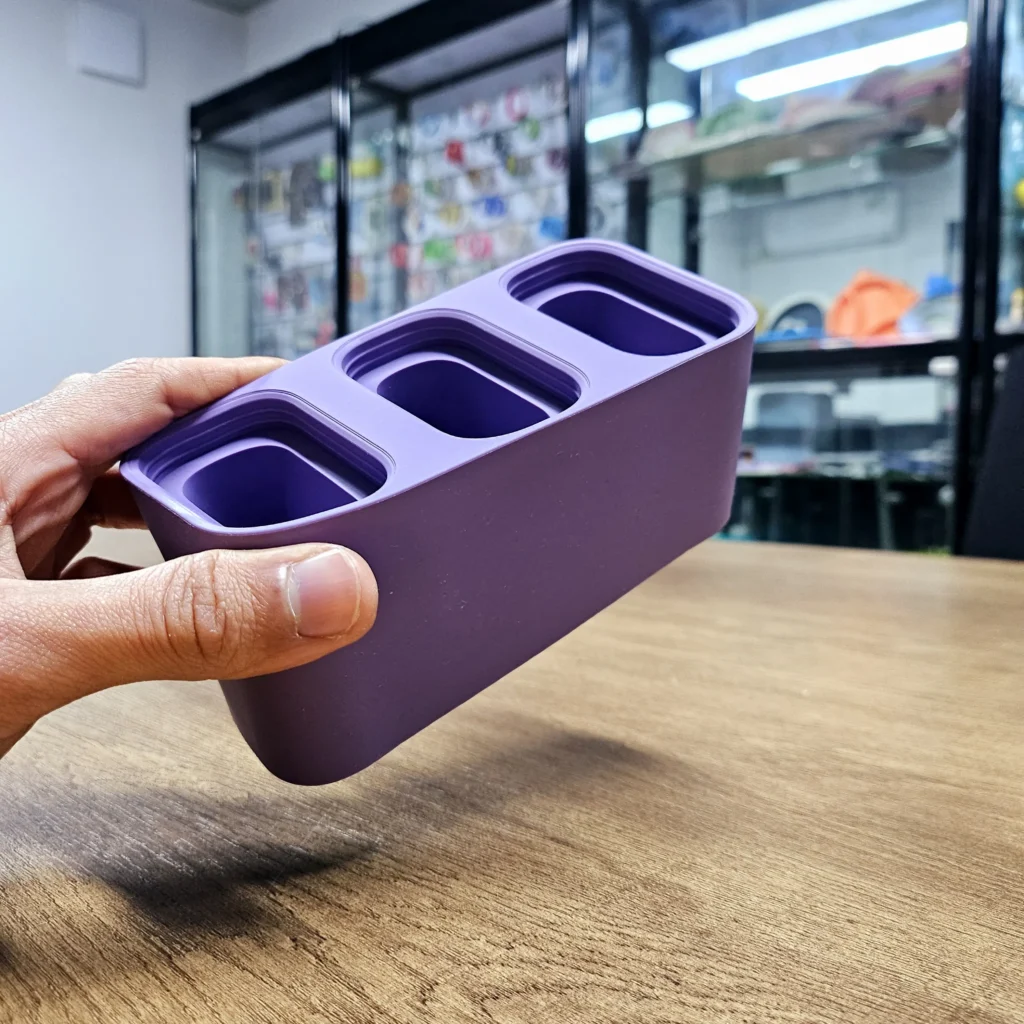

Case Studies & Product Examples:

Limited images of previous production are available. Our manufacturing journey began in 2005, leading to extensive experience and continuous skill refinement with every project.

We offer customized solutions that meet your specific needs.

- Additional photos

- Samples

- Tailored solutions based on your industry needs

Contact us to discuss your project in more detail or share a specific concept.

Materials Matter: The Silicone Grades and Additives We Rely On

Some information can be inferred from the testing methods mentioned in the technical data sheets:

- The “Flame Retardant Silicone” product contains 50% silicone and added flame retardants.

- The “Oil-Seeping Silicone” product contains 50% silicone and has a high oil content (>8%).

- The “Anti-Static Gas-Phase Silicone” product contains 50% silicone and has an anti-static effect.

As for fillers and additives:

- The “Flame Retardant Silicone” product contains halogen-free flame retardants.

- Some products (e.g., “Oil-Seeping Silicone”, “Anti-Static Gas-Phase Silicone”) have a specific mention of additives or fillers. If you need more detailed information on the materials employed contact us.

Compliance with International Standards

We adhere to safety and quality control standards by obtaining relevant certifications and complying with international regulations. Manufacturing Certifications at Dabojin.

Silicone Product Safety and Standards Portal.

Minimum Order Quantity: Flexible Options for Your Investment

We recognize that every project is distinct, and therefore, we don’t enforce a rigid minimum order quantity (MOQ). Economies of scale benefit larger orders, reducing production costs per unit. For custom silicone products increased quantities distribute fixed production expenses over a higher volume, resulting in lower costs.

For smaller orders, costs can be higher per unit. However, our prototyping services enable you to start projects with minimal initial investment. Prototypes enable you to test designs and materials before committing to larger production runs.

Our pricing is transparent, with clear and detailed invoices provided in advance. For detailed information on our minimum order quantity policies and how they affect pricing, please visit our dedicated page.

Typical Lead Time for Silicone Products

Once your design is ready and verified for manufacturability, the review process will take approximately one day. Following design approval, our CNC team creates the molds by programming the CNC machine to mill your design. This process typically takes 10-15 business days.

Prototyping typically takes place within the same day, contingent upon the design’s complexity.

We can produce up to 10,000 silicone gaskets per business day, enabling rapid fulfillment of large-scale orders.

Delivery times vary by destination. Shipments to the UK via DHL usually take 3 business days, while those to the USA typically take 4-5 business days. We offer various delivery options depending on your location and logistics preferences. Feel free to reach out directly, and we will provide an estimated lead time and cost based on your chosen delivery method.

Product Design assistance, prototyping, and tooling services

We offer comprehensive design assistance, prototyping, and tooling services for custom silicone products.

Our design support ensures that your product concept is manufacturable and optimized for performance. Prototyping and Design Assistance.

Our Pricing Structure for Silicone Products

We offer a transparent and flexible pricing model, customized to each project’s unique requirements. Our capabilities include CNC machining for both soft and hard tooling, as well as 3D printing for rapid prototyping. This enables us to produce accurate models with precise tolerances.

Our pricing typically includes the following components:

- Tooling Costs: This includes mold creation and any necessary assistive tools (e.g., needles and ejector pins). Tooling costs depend on the mold design’s complexity and the number of cavities needed. Lead times for tooling typically range from 10-15 business days, depending on the design’s complexity and approval process. CNC mold making service page.

- Our production costs depend on the type of silicone material used and the volume of units ordered. Larger orders typically benefit from volume discounts, which reduce the cost per item as production scales up.

- Shipping Fees: Shipping is charged separately based on your preferred logistics method and destination.

- Transaction Fees: We factor transaction fees into the total price. The payment method chosen (such as Alibaba Payment, PayPal, or bank transfer) also affects these fees.

- Deposit: We require a deposit for some orders.

For each project, we’ll create a customized quote that takes into account your specific needs. We also develop a tailored schedule that considers factors like product volume, tooling complexity, and material selection. We clearly outline all costs upfront and collaborate closely with you to ensure your project stays within budget.

If you have a specific project in mind, feel free to reach out for a personalized estimate.

Warranty, Returns, and Revisions Policy

At Dabojin, our focus is on producing quality silicone rubber products that meet customer requirements through precise manufacturing processes.

We have established comprehensive warranty, return, and revision policies that ensure timely issue resolution and customer satisfaction.

We provide a warranty against defects in materials or workmanship for a specified period after delivery. In case of a manufacturing defect, we will promptly replace the defective product with high quality products.

Since our products are custom-made, we don’t accept returns if they meet the agreed-upon specifications. We’ll identify and address any defects or issues that arise during production in a timely manner.

During the prototyping phase, we provide free revisions to address design, functionality, or manufacturability issues. We charge revisions after production starts based on their complexity.

If you experience any problems with your order, please reach out to us immediately. We’ll work closely with you to resolve the issue efficiently and effectively.

Technical Documentation and Compliance

We provide comprehensive technical documentation for all custom silicone products to ensure transparency and compliance with industry standards.

Documentation Includes:

- Material Safety Data Sheets (MSDS) : We provide detailed MSDS for all silicone materials used in production. Outlining properties, handling, and safety precautions.

- Certificates of Conformity : Our certificates demonstrate compliance with regulatory requirements and industry standards, such as RoHS and REACH, as well as client-specific requirements.

- Product Specifications : Detailed product specifications are available upon request, including material hardness, color, dimensions, and performance characteristics, ensuring the final product meets your needs.

Communication Process During the Production Cycle

We maintain open and transparent communication with our clients throughout the entire production cycle.

Communication Stages:

- Initial Order Confirmation : After receiving your order, we confirm the details via email or your preferred method.

- Design & Prototyping : We keep you updated on progress during design and prototyping stages. Sharing concepts, prototypes, or samples as needed. We collaborate with you to incorporate design or production changes promptly.

- Tooling & Production Updates : After design approval, our team begins tooling and production. We provide regular updates on mold creation, production schedules, and potential delays. You can reach out at any time for inquiries or updates.

- Final Product Review : Before final production, we confirm product details and ensure it meets expectations. If needed, we provide photos or video calls for review.

- Shipping & Delivery Notifications : Once your order is ready for shipment, we provide tracking details and estimated delivery times. We keep you informed on the status of your shipment.

Communication Channels:

You can reach us through email, social media, or schedule a video or phone call to get any questions answered.

Factory Tours and Inspections

We invite you to visit our facilities and can arrange a factory tour or inspection upon request.

Our factory is located at:

No. 49, Zhongao Road, Fenggang Town, Dongguan, Guangdong, China

Schedule a visit with us in advance so we can arrange for a productive and informative factory tour. We look forward to welcoming you and showing you our manufacturing capabilities. About Us Page.