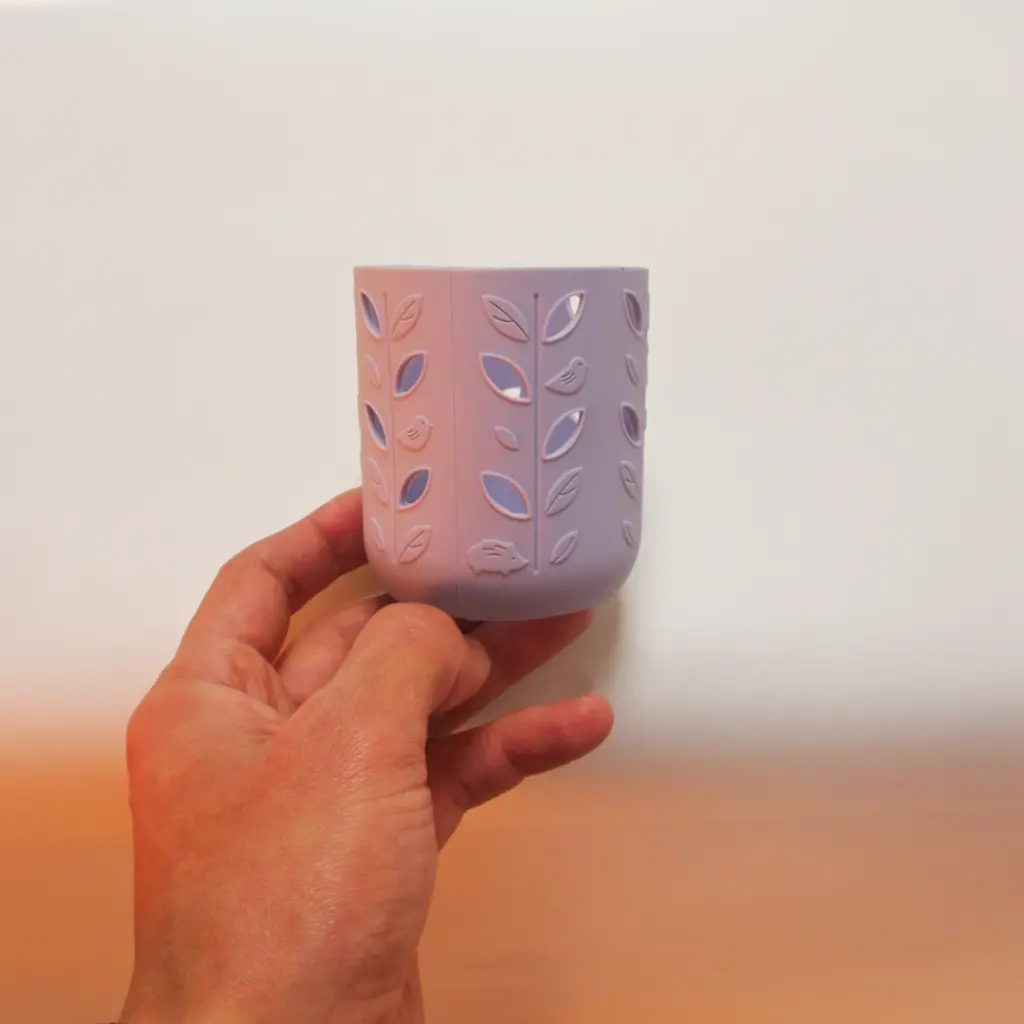

Custom silicone cups Direct from manufacturer

Our Comprehensive Custom Silicone Cup Fabrication Process

We offer custom silicone cup design and fabrication. Our process involves collaboration with you from initial concept to finished product.

Design: You provide specifications for cup size, shape, color, and any desired features. This includes sketches or digital drawings of your concept.

Our engineers create digital mold drawings based on your input, which are then used to program CNC machining equipment.

Manufacturing: Silicone material selection is based on your requirements (e.g., food-grade, heat resistant).

Post-molding finishing includes trimming, deburring, and inspection to ensure quality.

Prototyping: A prototype is molded upon your request to visualize the final product before mass production. This allows for adjustments and feedback prior to full manufacturing.

Let us know your specifications and we will guide you through the process of creating your custom silicone cups.

Silicone Cup Sleeves - Fabrication Overview

We fabricate custom silicone cup sleeves to provide protection, insulation, and grip enhancement for various beverage containers.

Features:

- Thermal Insulation: The sleeve acts as a barrier against heat transfer, minimizing burn risk and maintaining beverage temperature.

- Spill Containment: A tight-fitting design helps prevent spills during transportation or handling.

- Enhanced Grip: Textured surfaces provide increased friction for secure handling.

- Material Compatibility: Sleeves are manufactured from durable silicone compatible with a wide range of cup types and sizes.

Customization:

We offer customization options including:

- Sleeve dimensions to fit specific cup designs

- Color selection

- Embossing or printing for branding

Custom Silicone Cup Production Workflow

- Concept Submission: Provide detailed specifications and design parameters for your cups (sketches, images, or descriptions).

- Design & Material Selection: Engineering team analyzes requirements and proposes suitable silicone types and construction methods. For more information about the properties and applications of silicone rubber, you can visit [link to Wikipedia article on Silicone Rubber]

- Quote & Timeline: Comprehensive quote outlining materials, production timeframes, and fees provided.

- Prototype Fabrication: CAD-designed prototype molded using CNC machining techniques.

- Design Refinement: Prototype tested and iterated based on your feedback until final design approval.

- Mass Production & Quality Control: Final mold used for mass production; each cup inspected for dimensional accuracy, material compliance, and performance.

- Packaging & Shipping: Branded packaging and secure shipping.

- Ongoing Support: Available for post-production inquiries and future projects.

Request a Free Quote Today!

Submit your message, we reply within 24 hour

Call Us

Email Us

Meet Us

No. 49, Zhongao Road, Fenggang Town, Dongguan, Guangdong, China

Socials

Our Silicone Tested, and Ready For Your Needs.

At Dabojin, we make custom silicone products; we build trust through quality and safety. That’s why we put every type of silicone we offer through testing, including:

- Purity checks: To guarantee it's free from harmful contaminants.

- Safety tests: To make sure it won't pose a risk to your users.

- Compliance with industry regulations: RoHS, Proposition 65, EN 71-3 – we meet all the essential standards.

We provide detailed test data sheets for each silicone type, so you can confidently verify its suitability for your project. Visit our Silicone Compliance and Testing Hub: https://siliconedabojin.com/silicone-compliance-and-testing-hub/