Silicone Rapid Prototyping From Concept to Creation

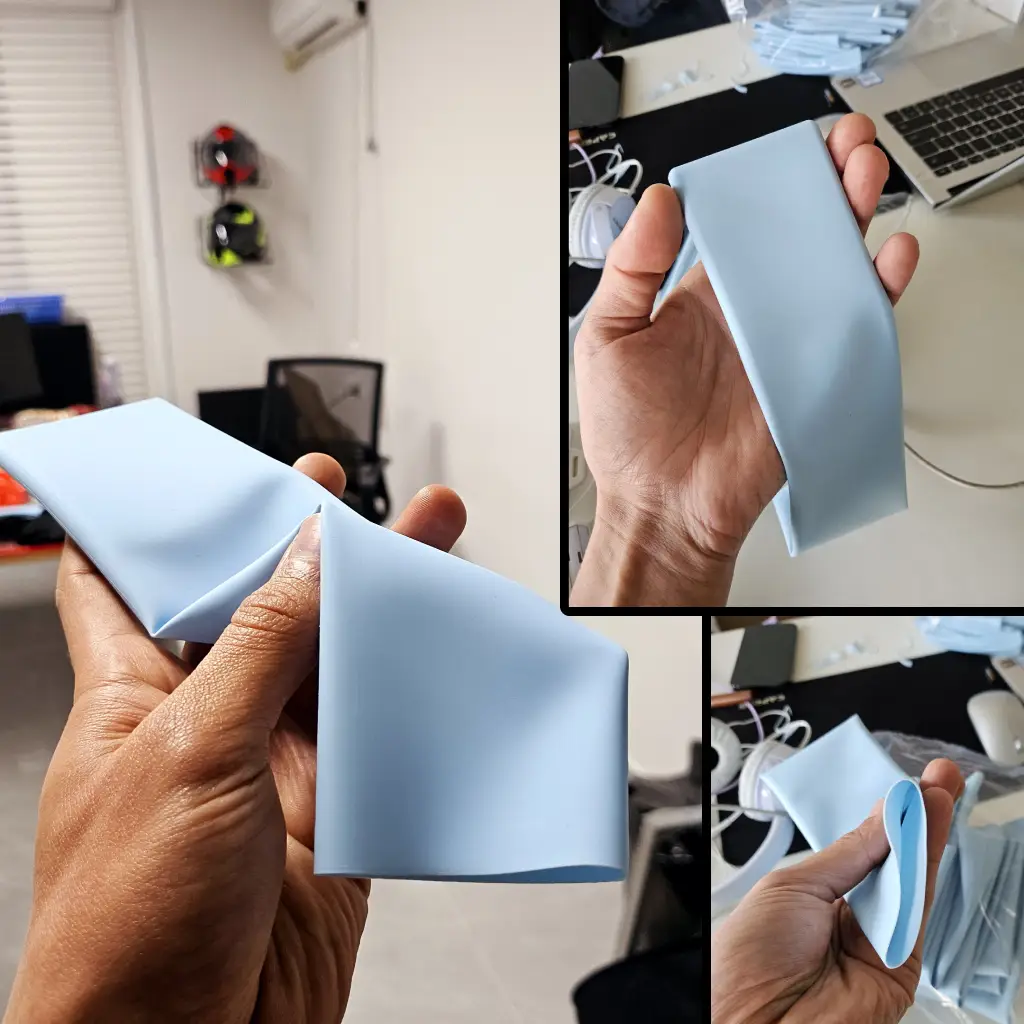

We provide fast and accurate creation of silicone prototypes using compression molding techniques. Our process takes your idea from concept to finished product with minimal delays. We create prototype parts that meet your specifications, ensuring a smooth transition from prototype to production.

Silicone Prototype for Functional Validation

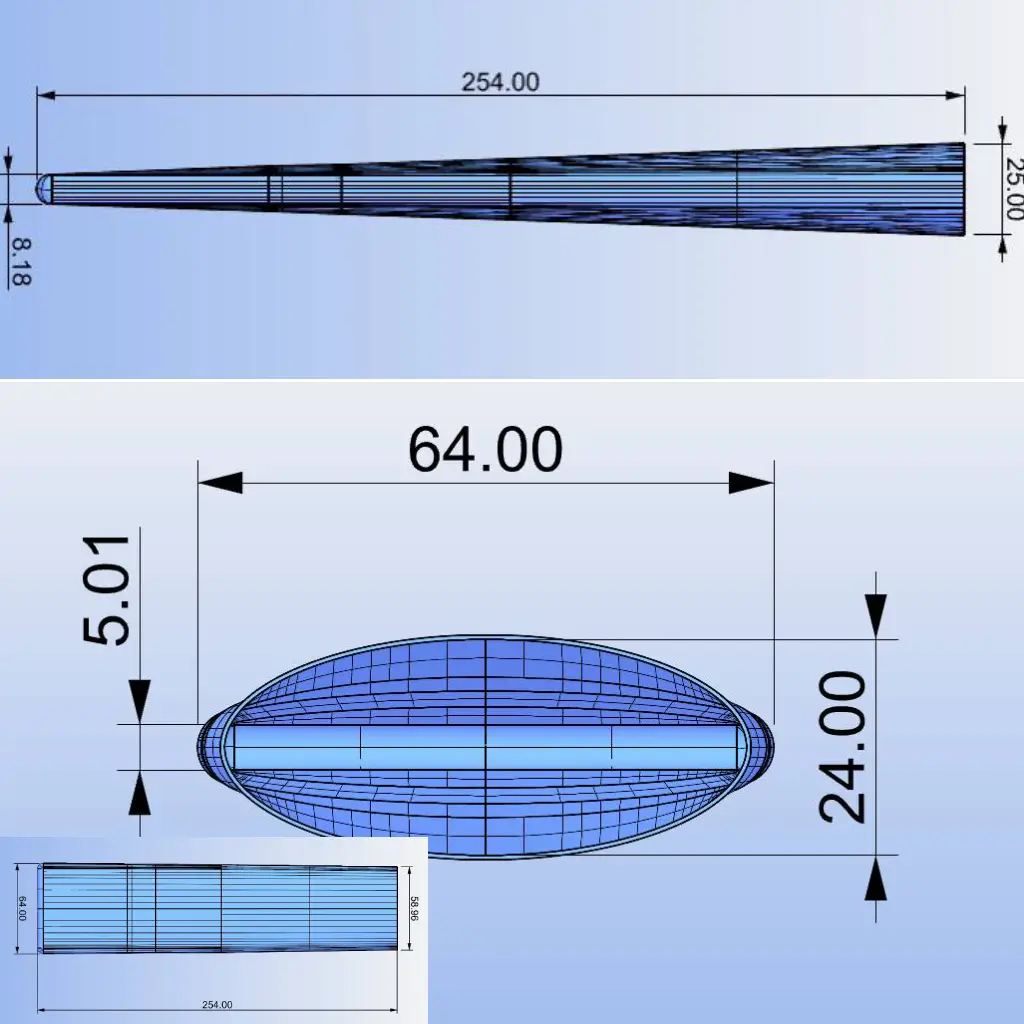

We achieve high precision with rapid prototyping, achieving dimensional tolerances of ±0.2/0.3 mm by controlling material properties and tolerances precisely. Our process involves using CNC milled molds to produce functionally accurate prototypes that closely match your design specifications.

Liquid Silicone Rubber (LSR) Prototype

Our liquid silicone rubber molding process ensures a smooth finish and precise dimensions, making it ideal for complex designs. We utilize our injection molding process for high volume production, which enables efficient results. Our team performs mold machining to ensure precise tolerances and optimal performance for your rubber prototype.

Silicone Rapid Prototyping Manufacturing Processes

Our team of engineers collaborates with you to refine your prototypes silicone parts, enhancing functionality, improving ergonomics, and maximizing production efficiency.

Choosing the Right Silicone Material

Choosing the right silicone material is critical to the success of your project. Our team collaborates with you to identify the most suitable material, taking into account your unique requirements.

Physical Properties of Silicone

Silicone exhibits notable flexibility, thermal stability, and can be molded into diverse shapes while maintaining integrity at extreme temperatures.

- Flexible: Molding machines shape and mold silicone into intricate part designs.

- High Thermal Stability: Silicone withstands extreme heat, maintaining shape and properties even at temperatures up to 250°C (482°F).

- Chemical Resistance: Silicone resists chemical attacks from most substances, including acids and bases.

Mechanical Properties of Silicone

Our custom silicone prototypes exhibit exceptional mechanical properties, making them suitable for a wide range of applications.

- High Tensile Strength: Silicone has a high tensile strength-to-weight ratio, ideal for lightweight applications where weight is a concern. Overmolding combines silicone with aramid fabrics and stainless steel wires to enhance rigidity.

- Low Density: Their low density makes them perfect for use in aerospace and other lightweight industries.

- Resistance to Compression: Silicone can withstand compressive forces without deforming.

Thermal Properties of Silicone

Resistance to UV Radiation: Many silicone materials are resistant to UV radiation, ensuring long-term durability even in outdoor and high-exposure environments.

Electrical Properties of Silicone

Our custom silicone prototypes exhibit exceptional electrical insulation and dielectric strength, making them suitable for high-voltage applications.

- Good Electrical Insulation: Silicone is an excellent insulator, commonly used in applications requiring high electrical insulation.

- Dielectric Strength: Silicone has a high dielectric strength, making it perfect for use in high-voltage industries.

Tooling for Rapid Prototyping Process

Selecting the right tooling material is crucial for your project’s success. Our team will work with you to determine the best material based on your specific needs.

Material Options for Tooling

For production tooling, we offer two primary material options: aluminum and SUS STAVAX (HRC 33). These materials excel in rapid prototyping due to their relatively low costs, quick machining capabilities, and optimal balance of strength, durability, and cost.

- Aluminum: A lightweight material perfect for smaller batches and prototyping.

- SUS STAVAX (HRC 33): A steel alloy offering a balance between strength, durability, and cost.

Alternative Tooling Options

In addition to traditional metal tooling, we also offer alternative options using 3D printing technology. This method allows for quick display and adjustments during the prototyping phase.

Benefits of Rapid Prototyping Tooling

Our rapid prototyping tooling offers numerous benefits, including:

- Quick Turnaround Times: Get your prototypes faster with our rapid prototyping capabilities.

- Cost-Effective: Reduce costs associated with traditional tooling methods for production parts.

- High-Quality Results: We deliver high-quality results with our silicone molds.

Silicone Prototype Manufacturer Contact Us!

Expect a reply within 24 hours