Silicone Overmolding Services for Custom Products

We offer silicone overmolding services for metal or plastic parts, from prototype to full production. Our team works closely with clients to design and manufacture customized solutions that meet their needs.

- Products designed to fit existing parts

- Variety of finish options available, from textured to matte finish

- Source and supply other materials required for bonding, such as thermoplastics or metals

- Utilize soft tooling and hard tooling options for prototype and production parts

- Support small businesses, large corporations, and individual clients with tailored services

- Provide competitive pricing and flexible delivery terms

If you have a project in mind, please submit your design or inquiry for our review. We’ll be happy to discuss how we can help.

Our Overmolding Services Span Diverse Industries

Case Studies

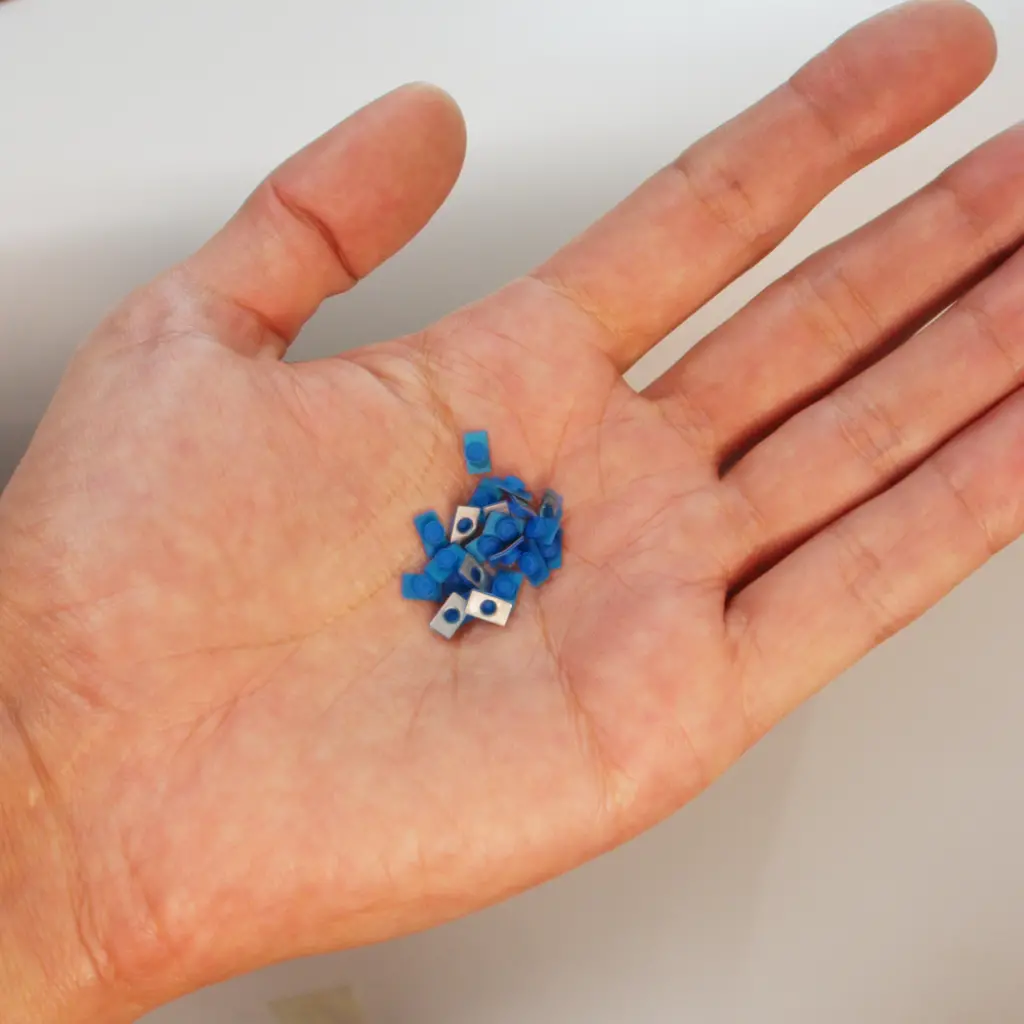

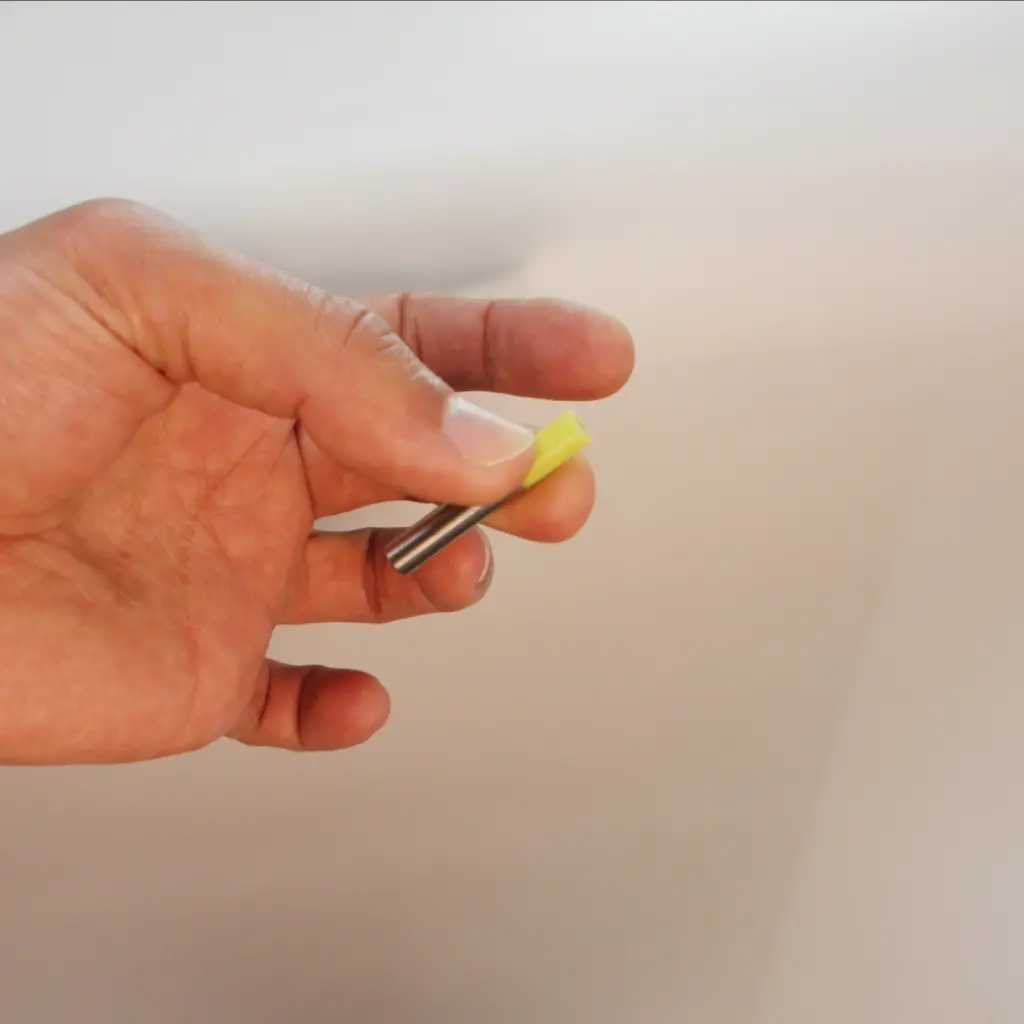

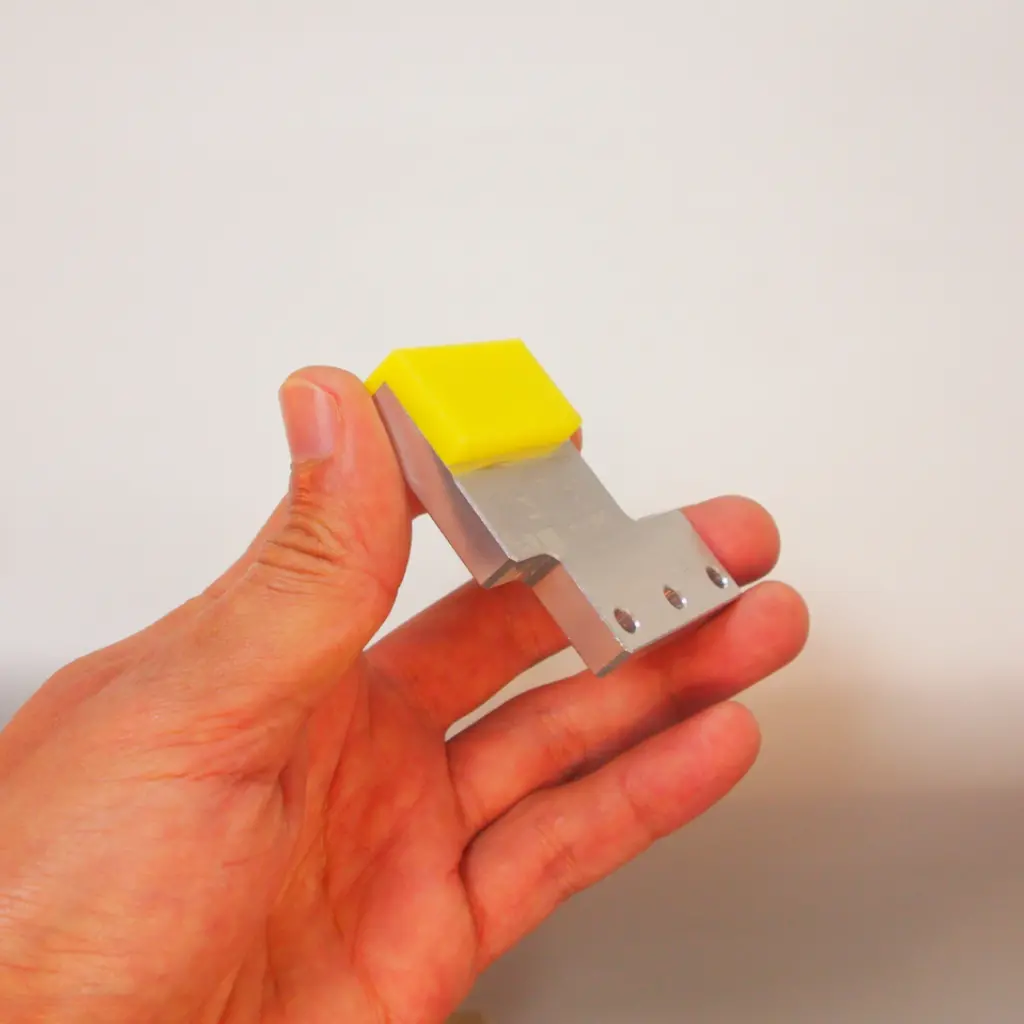

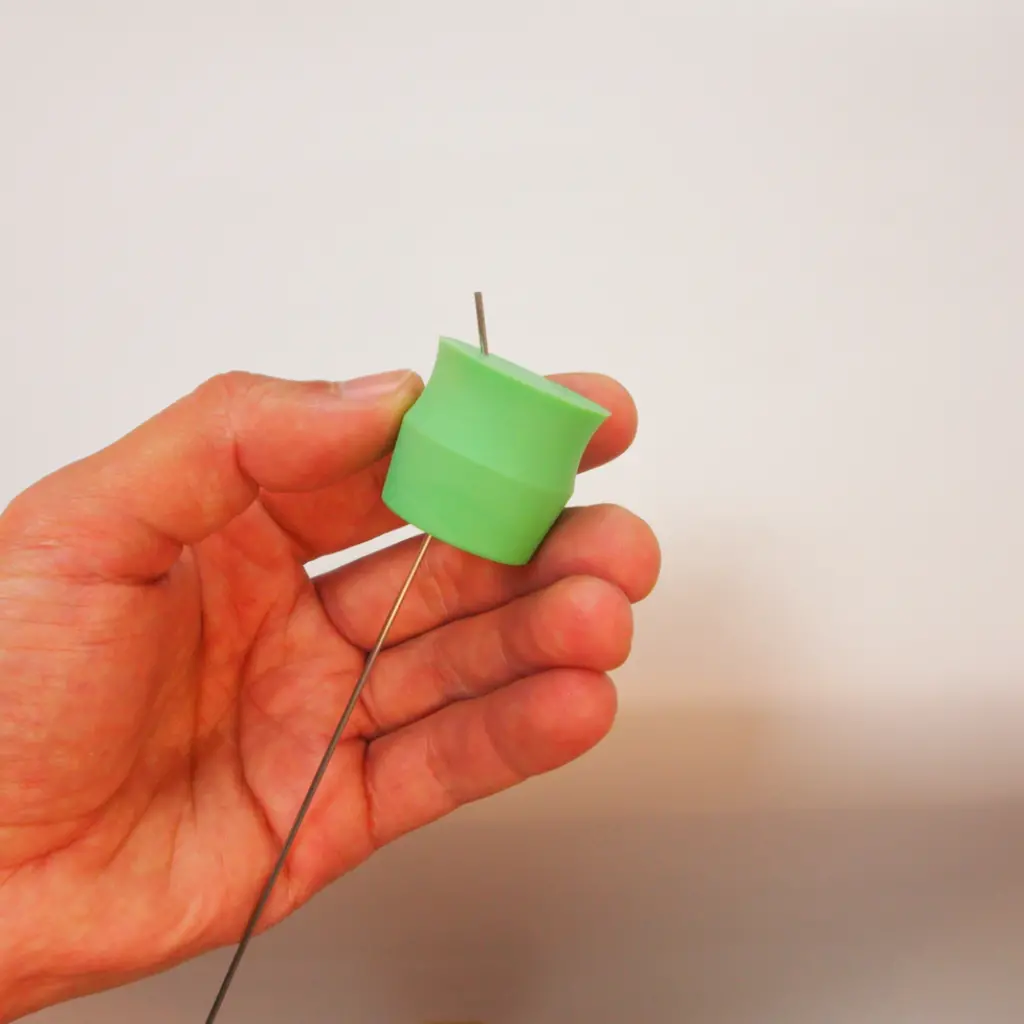

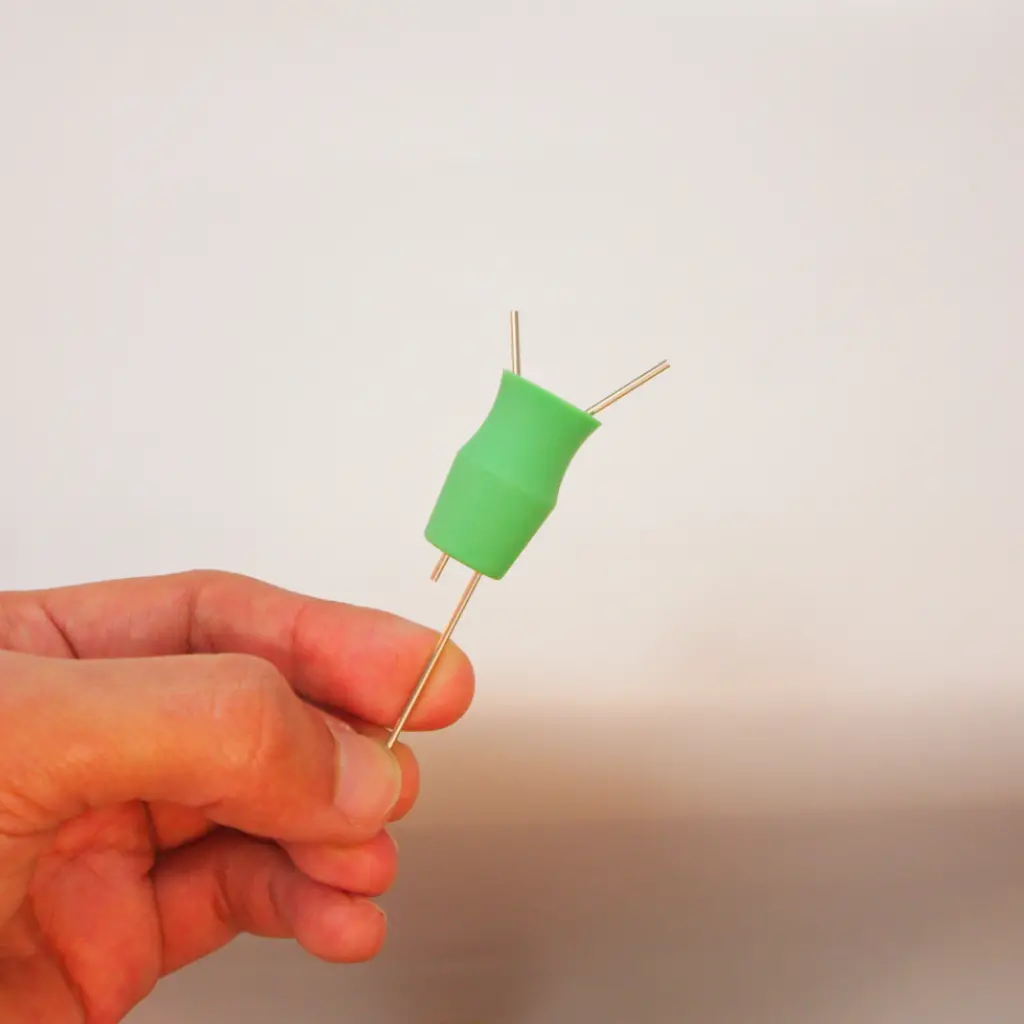

Our silicone overmolding expertise spans diverse industries. Examples include green stoppers with 304 needles for labs, DC connectors for electronics, and dash pull knobs for automotive.

We ensure a robust mechanical bond between silicone and metal/plastic substrates, utilizing a cost-effective overmolding process. Our focus includes delivering accuracy and quality in injection or compression molding for overmolded parts. Explore our portfolio for efficient and customized solutions.

Custom Solutions for Different Needs in Silicone Overmolding

We offer customized solutions to meet your specific requirements.

Our capabilities include:

- Dimensional Tolerances: Achieving tolerances of 0.1-0.5 mm with precise molds and tooling, allowing for tight fits and reliable performance.

- Material Properties: Our silicones have been extensively tested and documented, ensuring consistent quality across all materials. We provide silicone compounds that are resistant to environmental factors such as water, chemicals, and UV radiation, making them suitable for applications in harsh conditions like outdoor or industrial settings.

- Complex Geometries: Designing molds for complex shapes and features like undercuts, cores, or inserts, enabling you to create intricate parts with high precision.

- Multi-cavity Molds: Producing multiple parts simultaneously with increased efficiency and reduced production time, allowing you to meet demanding production volumes without sacrificing quality or increasing costs.

- Color Matching: Developing custom color combinations using Pantone colors, so that your products can be uniquely colored to match specific design requirements. Our silicone compounds can also be formulated with various colors or textures to add an extra layer of customization.

Silicone Overmolding Process: From Requirements to Mass Production

-

Requirements Gathering: Engage with the client. Review engineering aspects and suggest a solution. Move forward with approval.

-

Mold Design: Design a functional mold for both prototypes and mass production. Test for structural integrity and scalability.

-

CNC Mold Making: Use CNC machines to create precise metal molds. Prepare molds for prototype and mass production phases.

-

Prototype Silicone Overmolding: Overmold the prototype using the finalized mold.

-

Prototype Review: Compare the prototype against project specifications. Conduct iterative testing and adjustments. Opt for client review or in-house testing.

-

Transition to Mass Production: Start mass production after prototype approval. Use the finalized mold and process. Scale up production while ensuring quality and compliance.

Silicone Material Selection for Overmolding

Choosing the right silicone for overmolding tasks requires careful consideration, as it impacts the final product’s performance. The Platinum Extrusion Silicone series offers hardness levels from 40 to 80 A Shore. This lets you choose the right toughness for projects like LED co-extrusion, sleeves, neon strips, tubes, or shaped strips.

If you need clear, bubble-free materials, consider the High Transparency Gas Phase Silicone series (Zy-8530 to Zy-8580). For bouncy items like seals, gaskets, or sports seat cushions, the High Rebound Gas-Phase Silicone (Zy-7830 to Zy-7880) is great.

Let us know what you need, and we’ll assist you in choosing the right materials. You can also explore our silicones and their features on our website. We offer detailed information and test data for each type.

Comprehensive Silicone Overmolding Solutions with Quality Standards

We specialize in silicone overmolding for various industries. Our quality control is thorough, production capabilities are flexible, and service is fast. We maintain open communication, ensure compliance with industry standards, and can provide client references.

ISO 9001: Ensuring consistent quality in our production processes.

ISO 45001: Focusing on improving workplace safety and health in our operations.

ISO 14001: Aiding in reducing the environmental impacts of our operations.

FDA Standards: Ensuring the safety and compliance of our products, especially for medical and food applications.

Submit Your Request for Silicone Overmolding Services

Our team is ready to provide personalized support and solutions customized to your specific needs. Fill out the form, and we will get back to you within 24 hours.