Custom Silicone Equipment for Various Industries

Table of Contents

- Custom Silicone Industrial Equipment Manufactured for Various Industries

- Benefits of Custom Silicone Industrial Equipment

- Designing and Manufacturing Industrial Equipment with Silicone

- Applications of Custom Silicone Industrial Equipment

- Chemical Processing and Handling Equipment

- Heavy Industry Equipment

- Laboratory Equipment and Instruments

- Other Industrial Applications

- The Benefits of Working with a Specialist in Custom Silicone Manufacturing

- Case Studies and Real World Examples

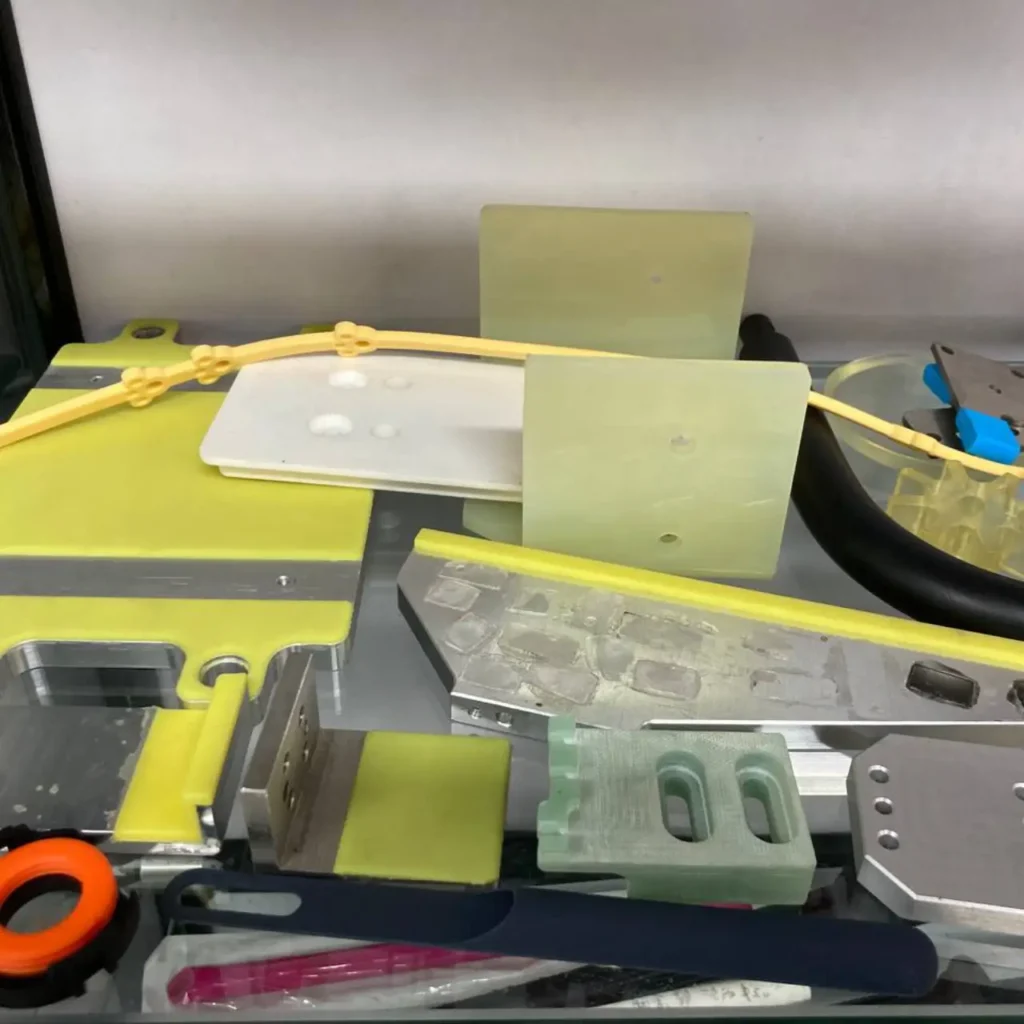

Custom Silicone Industrial Equipment Manufactured for Various Industries

Custom silicone industrial equipment is designed to provide a unique solution for industries seeking high-purity and chemical resistance properties in their equipment. Unlike traditional materials, silicone offers exceptional durability, flexibility, and cost-effectiveness, making it an attractive option for manufacturers looking to upgrade their existing equipment or design new ones from scratch. Get in touch with our team of experts at Dabojin to discuss your custom silicone industrial equipment needs and receive a quote.

Benefits of Custom Silicone Industrial Equipment

Custom silicone industrial equipment offers several benefits over traditional materials, including:

- High-purity and chemical resistance properties: Silicone is renowned for its exceptional resistance to chemicals, heat, and extreme temperatures. This makes them an ideal choice for applications where contamination or chemical exposure is a concern.

- Ability to withstand extreme temperatures and pressures: Silicone equipment can operate in environments with temperatures ranging from -50°C to 200°C (-58°F to 392°F) and pressures up to at least 15 Mpa, exhibiting physical properties such as semi-transparent appearance, varied plasticity, hardness (Shore A units), density (g/cm³), tensile strength (Mpa), elongation (%), and tear strength (KN/m) depending on the specific type of silicone product.

- Customization options for complex geometries and designs: Silicone can be molded into intricate shapes, making them suitable for applications where traditional materials cannot accommodate complex geometries.

- Cost-effectiveness compared to traditional materials: Custom silicone equipment often proves to be more cost-effective in the long run due to its durability, low maintenance requirements, and resistance to wear and tear.

Designing and Manufacturing Industrial Equipment with Silicone

The design and manufacturing process for custom silicone industrial equipment involves several stages:

- 3D modeling and prototyping: The first step is to create a 3D model of the desired equipment using computer-aided design (CAD) software or other digital tools.

- Manufacturing techniques: Depending on the complexity and size of the equipment, various manufacturing techniques can be employed, including injection molding, compression molding, die cutting, dispersion molding, overmolding, and more.

- Material selection and testing procedures: The type of silicone used will depend on the specific application and requirements. Testing procedures are conducted to ensure that the equipment meets the necessary standards for purity, chemical resistance, and durability.

Applications of Custom Silicone Industrial Equipment

Custom silicone industrial equipment has numerous applications across various industries. Its unique properties make it an ideal choice for handling chemicals, manufacturing equipment, laboratory settings, and other high-temperature applications.

Chemical Processing and Handling Equipment

Silicone is widely used in chemical processing due to its high-purity properties, making them ideal for handling chemicals. Some examples of chemical processing and handling equipment made from custom silicone include:

- Piping systems: Custom silicone piping systems are designed to transport chemicals with minimal risk of leakage or contamination.

- Valves and fittings: Silicone valves and fittings are used to control the flow of chemicals and prevent back-flow.

- Tanks and vessels: Custom silicone tanks and vessels are used for storing and processing chemicals.

Heavy Industry Equipment

In heavy industry, silicone is used for manufacturing equipment such as oil and gas, power generation, and other high-temperature applications. Some examples of heavy industry equipment made from custom silicone include:

- Heat exchangers: Custom silicone heat exchangers are used to transfer heat in high-temperature applications.

- Pumps and compressors: Silicone pumps and compressors are used to move fluids and gases in industrial processes.

- Insulators and gaskets: Custom silicone insulators and gaskets are used to seal and insulate equipment in heavy industry applications.

Laboratory Equipment and Instruments

Silicone is used in laboratory settings due to its chemical resistance, purity, and low contamination risk. Some examples of laboratory equipment made from custom silicone include:

- Pipettes and syringes: Custom silicone pipettes and syringes are used to accurately measure and transfer liquids.

- Tubes and columns: Silicone tubes and columns are used in chromatography and other laboratory techniques.

- Sampling equipment: Custom silicone sampling equipment is used for collecting and handling samples in laboratory settings.

Other Industrial Applications

Custom silicone equipment is also used in food processing, pharmaceuticals, and medical devices. Some examples include:

- Food processing: Custom silicone equipment is used in food processing plants to handle and process food products.

- Pharmaceuticals: Silicone equipment is used in pharmaceutical manufacturing to produce high-quality medicines.

- Medical devices: Custom silicone medical devices are used in healthcare facilities for medical procedures and treatments.

The Benefits of Working with a Specialist in Custom Silicone Manufacturing

When working on custom silicone manufacturing projects, it’s essential to collaborate with an experienced specialist who understands the intricacies of silicone production. This collaboration can provide numerous benefits:

- Expertise and experience: A specialist will bring their knowledge and expertise to the table, ensuring that your equipment meets the necessary standards.

- Customized solutions: Specialists can offer customized solutions for complex geometries and designs, making them ideal for applications where traditional materials cannot accommodate these features.

- Quality control and testing procedures: A reputable specialist will adhere to quality control and testing procedures, guaranteeing that their products meet the required purity, chemical resistance, and durability standards.

Case Studies and Real World Examples

In various industrial applications, we have successfully provided custom-made rubber gear, silicone rod bearings, and silicone rubber tires that meet the demands of heavy-duty machinery and harsh environments.

Our extensive portfolio has helped us serve clients across multiple industries, delivering solutions that extend equipment life, reduce maintenance costs, and improve productivity.