Custom Silicone Products Manufacturing Services

At Dabojin we provide specialized silicone manufacturing solutions tailored to your unique needs. Our expertise encompasses a comprehensive range of services designed for product development and mass production using silicone materials.

Silicone product development services

Silicone Compression Molding

Silicone compression molding shapes durable, custom parts efficiently. Our process suits various volumes, ensuring quality and meeting strict standards. Simple, direct, effective.

Advantages: Best suited for large quantities with uniform thickness. Low tooling cost.

Disadvantages: Provides less dimensional precision compared to injection molding.

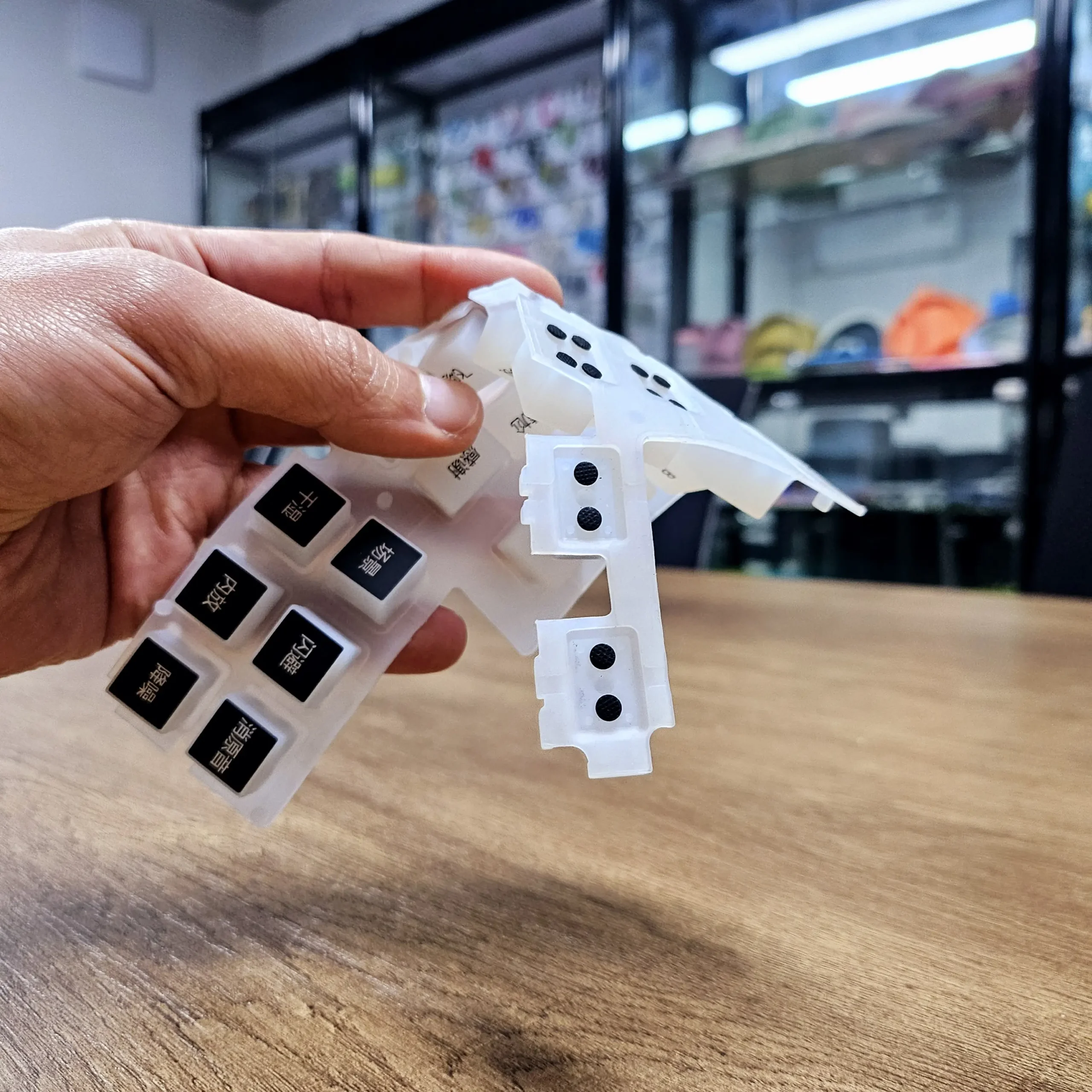

Silicone Overmolding Service

Silicone overmolding bonds rubber to substrates like metal and plastic. It’s ideal for unique, durable products, especially in custom devices and electronics.

Advantages: Enhances functionality and aesthetics. Ideal for parts requiring a soft touch or protection.

Disadvantages: Requires multiple stages. Higher material costs.

LSR Injection Molding Service

Liquid silicone injection molding (LSIM) is a precise manufacturing method that uses fluid silicone to create strong, detailed parts.

Advantages: Efficient for mass production. Precise control over dimensions and properties.

Disadvantages: High initial cost for tooling. Requires more technical expertise.

Silicone Extrusion Molding

Silicone rubber extrusion molding shapes durable, versatile products by forcing silicone through a die to create items like seals and tubing. This process meets strict industry standards, ensuring reliability in harsh conditions across multiple sectors. Every product reflects our commitment to quality and precision.

Advantages: Perfect for tubes, strips, and profiles. Consistent cross-sections. Efficient for long runs.

Disadvantages: Limited to continuous, uniform cross-sections. Setup can be complex.

CNC Mold Making Service

CNC mold making crafts precise molds for silicone products, starting with a detailed CAD design. This process ensures each mold perfectly matches its blueprint, using advanced CNC techniques for exact cuts—critical for high-quality molds.

Materials such as steel, aluminum, and titanium are commonly used, each offering unique advantages in durability and heat resistance. Proper mold care, temperature control, and intelligent design enhance longevity and quality, making CNC mold making essential for precision silicone manufacturing.

Silicone Die Cutting Service

Silicone die cutting is essential for shaping parts like seals and gaskets, leveraging silicone’s flexibility and heat resistance. This process utilizes techniques such as flatbed, rotary, laser, kiss, and perforation cutting, ensuring precision for custom applications in industries like automotive and electronics.

Advantages: Ideal for thin, flat parts. Ensures even sizes and detailed shapes.

Disadvantages: Limited to two-dimensional shapes. Less versatile for complex designs.

Considerations for Choosing the Right Process in Silicone Products Manufacturing

When determining the most suitable manufacturing process for your silicone product, several key factors come into play:

- Design & Functionality Requirements: We assess the specific features needed for your product to ensure it meets functionality and design criteria effectively.

- Quantity Needed: Based on whether you require prototypes or large-scale production, we decide the best approach to meet your needs efficiently.

- Cost-Effectiveness: We balance the use of premium materials with budget-friendly options to optimize costs while maintaining quality standards.

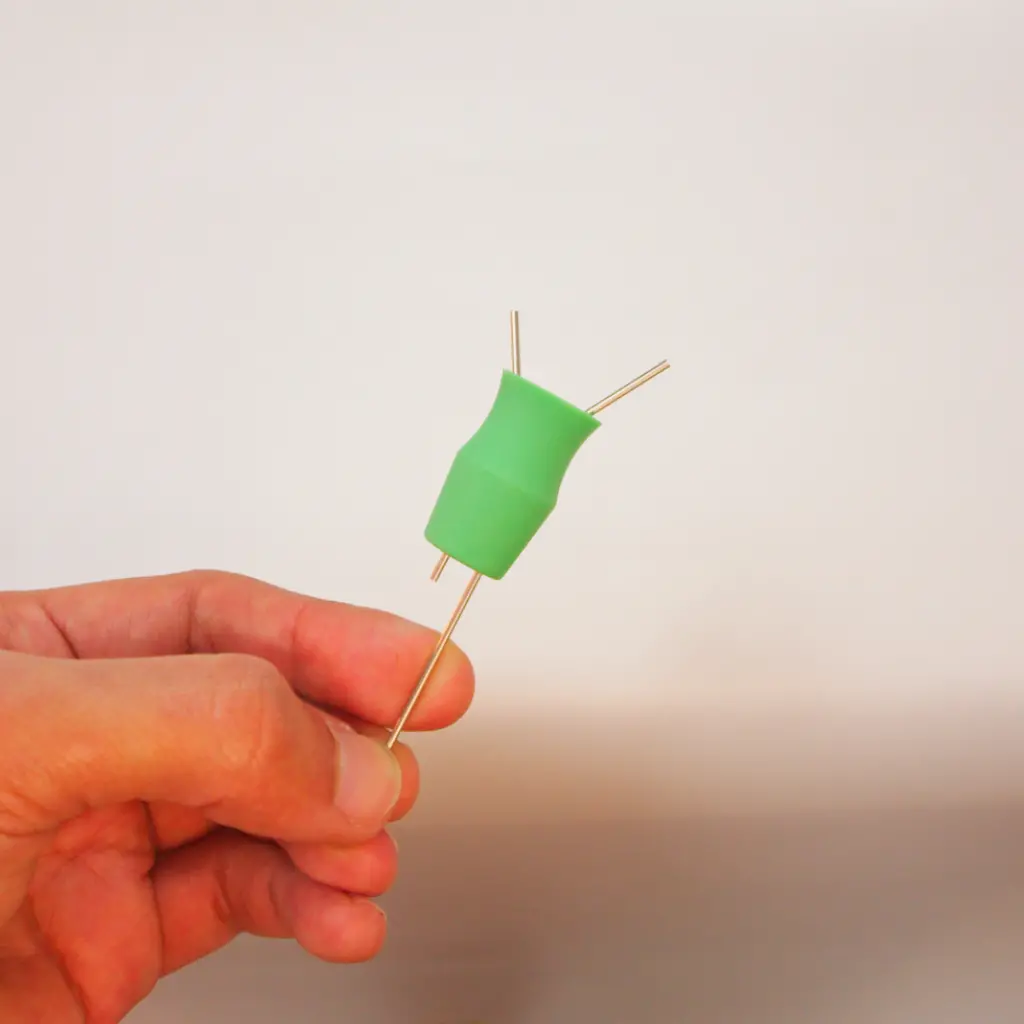

Example

For LED silicone sleeves, our experience shows that manufacturing using Silicone Extrusion Molding is more efficient than Compression Molding. This method allows for the creation of long, thin shapes that can be precisely cut to desired sizes, enhancing both efficiency and cost-effectiveness.

By carefully evaluating these factors, we tailor our services to your specific requirements, ensuring robust documentation and process validation.