Silicone Heat Exchanger Gaskets in Microbiology Labs

We design and make custom silicone heat exchanger gaskets for microbiology. Our gaskets are sterile, chemical-resistant, heat-tolerant, biocompatible, and customizable. They meet strict industry standards and are built to last. Contact us to start customizing your solution today.

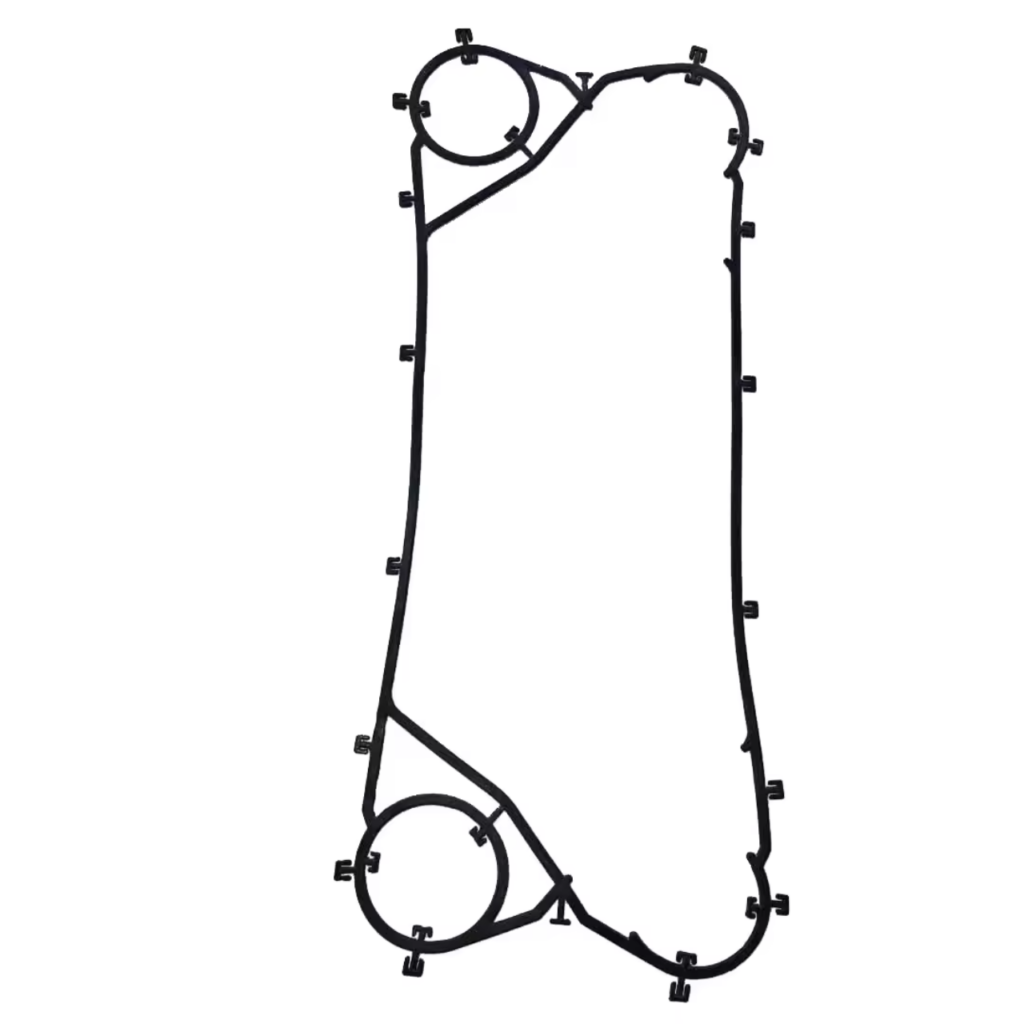

From Your Sketch to Our Specialty: Silicone Heat Exchanger Gaskets

We make gaskets from various silicone types to fit your needs. Choose Platinum Cured Silicone for its biocompatibility and strength, ideal for microbiology. For high heat, choose High-Temperature Resistant Silicone. Each material has specifications like tensile strength and tear strength for precise customization.

FAQs: Silicone Heat Exchanger Gaskets

Please contact us for details on the minimum order quantity.

We review your design and provide feedback.

You can revise the design until you are satisfied.

We manufacture a prototype for your approval.

Heat exchanger gaskets are made through several steps, based on material and design. First, we select the right material. Then, we machine a mold for the gasket. For silicone gaskets, we use compression molding. The silicone stays in the mold under heat and pressure until it cures. After curing, we remove the gasket and trim any excess material. We conduct quality control tests to ensure it meets all standards. Once approved, the gaskets are packaged and prepared for shipping.

Yes, we provide a sample for your approval.

We ship them to your specified location.

Contact us with your previous order details to reorder.

Please contact us for details on the minimum order quantity.

Overview of Heat Exchanger Gaskets

Silicone is valued in microbiology for its biocompatibility, thermal stability, and chemical resistance. These traits are crucial for applications needing strict temperature control and contamination prevention. Silicone gaskets are key in heat exchange systems, maintaining conditions for microbial growth. They withstand mechanical stress and chemical exposure from cleaning and sterilization. Silicone’s qualities ensure the integrity and sterility of microbiological processes.