Debunking Myths About Silicone and Plastic A Detailed Analysis

The debate between silicone and plastic has been ongoing, with both materials playing significant roles in modern manufacturing and everyday products. However, misconceptions about their environmental impact, safety, and recyclability often lead to confusion. This article aims to clarify these misconceptions by providing a detailed analysis based on real-world data and examples, focusing on recyclability, biodegradability, and food safety. By the end, you’ll be equipped with the knowledge to make a well-informed choice between silicone and plastic.

1. Recyclability

The Challenges of Recycling Silicone Compared to Plastic

Silicone is often perceived as difficult to recycle compared to plastic. While it’s true that silicone recycling is less common and more complex, it is far from impossible. In fact, many companies, including us Dabojin custom silicone manufacturer, engage in regular recycling practices.

Data Overview:

- In Dabojin facility, silicone waste is collected weekly and sent to a recycling company where it is typically processed and sold to third-party chemical plants. The recycled silicone is often repurposed in chemical applications, such as in the production of sealants, adhesives, or industrial coatings.

Recycling Methods:

Several methods are used in the industry to recycle silicone, including physical breaking, catalytic cracking, and various chemical processes. Each method has its own set of challenges, particularly regarding energy consumption and the ability to fully reclaim high-quality silicone.

Discussion:

While the exact products made from recycled silicone can vary, it is reasonable to infer that much of it ends up in applications where its chemical properties are valued, even if it’s not directly used to create new silicone products. The main challenges in silicone recycling include the high energy requirements and the limited scope of some recycling methods, which can make the process more complex and less efficient than plastic recycling.

Conclusion:

Recycling silicone is not only possible but actively practiced in industries. Although it faces certain challenges, ongoing efforts are improving the processes, making silicone recycling more viable and environmentally beneficial.

2. Biodegradability

Biodegradability and Environmental Impact

One of the most significant concerns regarding materials today is their impact on the environment, particularly in terms of biodegradability. Silicone and plastic both have long lifespans, but their environmental impacts differ significantly.

Data Overview:

- Silicone, particularly polydimethylsiloxane (PDMS), is known for being environmentally inert. This means that while it does not biodegrade easily, it also doesn’t release harmful substances into the environment. In contrast, plastics like polyethylene (PE) are notoriously difficult to degrade and can persist in ecosystems for hundreds of years, causing significant environmental damage.

Additional Reference:

Recent studies, such as those on the biodegradation of PE microplastics by mealworms, reveal that even when biological processes break down plastics, they can still cause stress and damage to the environment. The microplastics resulting from partial degradation can disrupt ecosystems and pose a threat to wildlife.

Discussion:

Silicone’s non-biodegradability is often viewed negatively, but its inert nature means that it doesn’t contribute to environmental toxicity in the same way that plastics do. While plastics break down into smaller particles that can accumulate in food chains and cause long-term harm, silicone remains stable, posing less risk of environmental contamination.

Conclusion:

While neither silicone nor plastic biodegrades quickly, silicone’s inert nature makes it a safer choice in terms of long-term environmental impact. Non-biodegradable plastics, on the other hand, contribute significantly to pollution and ecological disruption, making them more problematic in the context of sustainability.

3. Food Safety and High-Fat Foods

FDA Certification and Safety Standards

Safety in food applications is a critical factor when choosing materials, especially for items that come into direct contact with food. Silicone is widely used in kitchenware, but there are concerns about its interaction with high-fat foods.

Data Overview:

- Dabojin products are FDA-approved, indicating that they meet stringent safety standards for food contact. However, specific tests on the interaction between silicone and high-fat foods are not detailed in the approval documentation.

Discussion:

The FDA approval process for food-contact materials is thorough, covering a wide range of safety concerns. While the exact testing protocols for high-fat foods may not be specified, the comprehensive nature of FDA testing suggests that these products are safe for a variety of food types. However, as with any material, further testing specifically focused on high-fat foods could provide additional reassurance.

Conclusion:

FDA-approved silicone products are considered safe for use in food applications, including those involving high-fat content. While specific testing on high-fat foods might be lacking, the overall safety of silicone in the kitchen is well-supported by existing certifications.

4. General Comparison of Silicone vs. Plastic

When choosing between silicone and plastic, it’s important to consider the specific application. Both materials have their strengths, but they are not always interchangeable.

Data Overview:

- Silicone: Food-grade transparent silicone (shore A 70) used in silicone compression molding for a prototype costs around $450, including tooling.

- Plastic: BASF Elastollan 1170 A 10 FC, a plastic material used in injection molding, typically costs $2,310, including tooling.

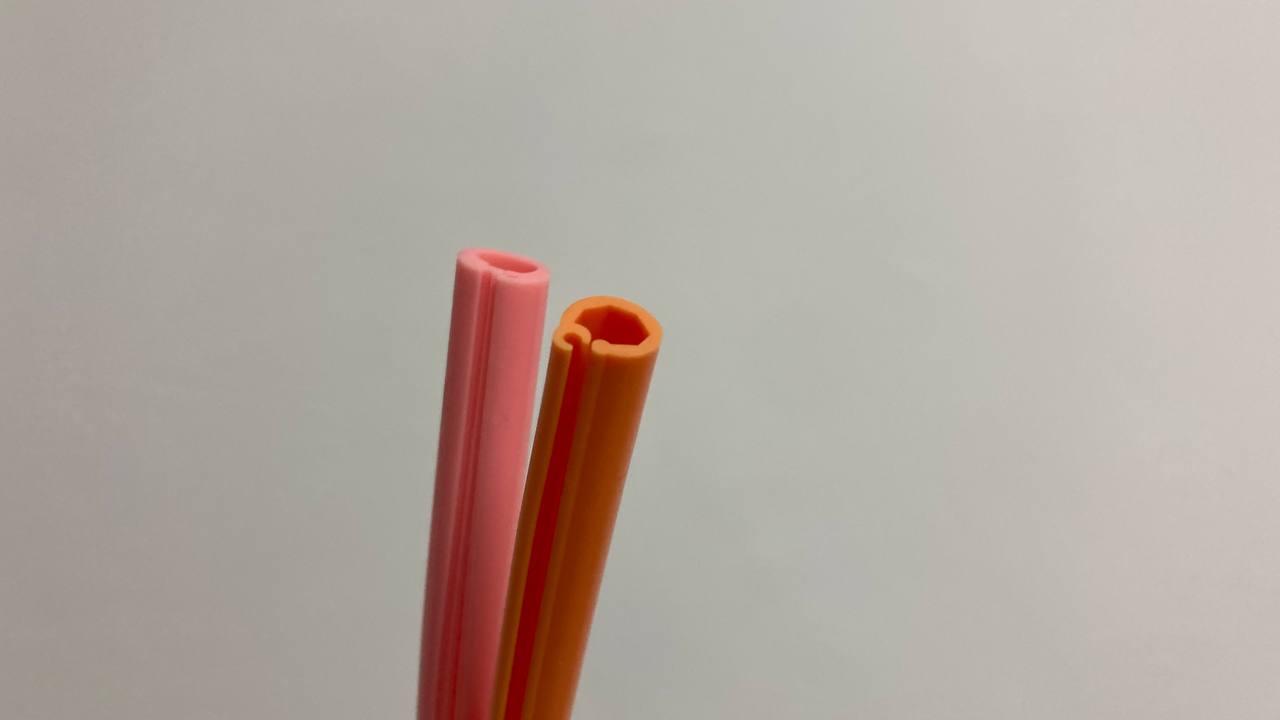

Silicone Advantage Example:

One example of silicone’s superiority is in the design of a reusable, easy-to-clean straw for milkshakes. Unlike plastic, which might degrade or be difficult to clean, silicone’s durability and flexibility make it ideal for such applications.

Discussion:

Silicone’s durability, reusability, and safety in various applications give it a clear advantage in contexts where these factors are prioritized. However, it’s also important to acknowledge that plastic remains the better choice in other scenarios, particularly where cost efficiency and material properties like rigidity are more critical.

Conclusion:

Silicone and plastic each have their own strengths and limitations. The choice between them should be based on the specific needs of the application, with silicone being favored in scenarios where reusability, safety, and durability are paramount.

Conclusion

In the ongoing debate between silicone and plastic, it’s clear that both materials have their place. By understanding the nuances of recyclability, biodegradability, and safety, consumers and manufacturers can make informed decisions that align with their sustainability goals and application needs. While no material is perfect, silicone’s unique properties make it a valuable alternative to plastic in many cases, particularly where long-term durability and safety are required.