Compression Molding Products: Shaping Your Idea

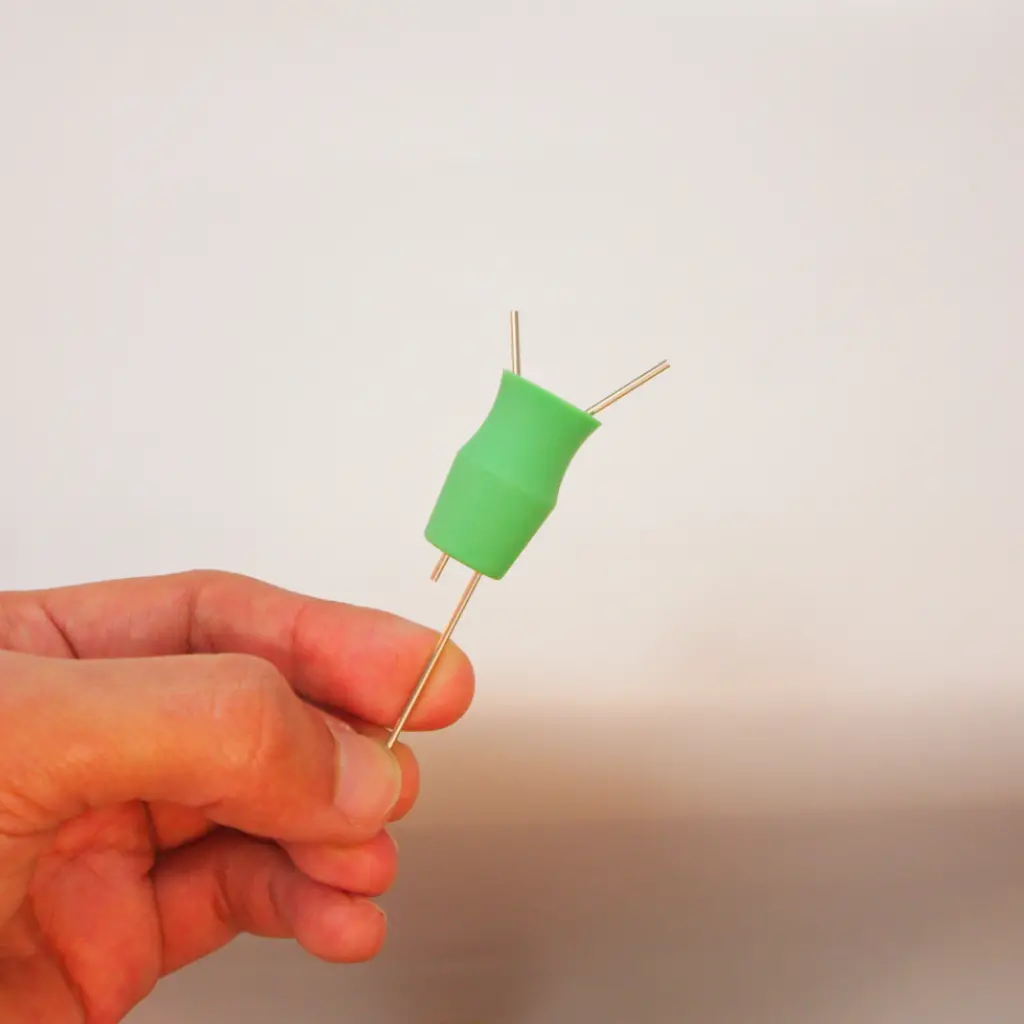

Compression molding products is a manufacturing process that shapes thermosetting materials into specific forms by applying heat and pressure. This technique is widely used in industries such as automotive, aerospace, and medical devices to produce durable and precise components.

Applications Across Industries

- Automotive: Production of gaskets, seals, and other critical rubber components.

- Aerospace: Manufacturing components requiring high durability and precision.

- Medical Devices: Creation of parts for equipment that demands both functionality and safety.

Advantages of Compression Molding

- Sustainability: Eco-friendly process with less material waste compared to traditional methods. This reduces environmental impact, aligning with global sustainability goals.

- Precision: Achieves tight tolerances (e.g., ±0.2 mm) ensuring high-quality products.

- Versatility: Suitable for various materials like silicone and capable of handling complex designs.

Technical Capabilities

- Tolerances: Capable of producing components within ±0.2/0.3 mm, ideal for functional validation in rapid prototyping.

- Materials: Utilizes silicone rubber for smooth finishes and precise dimensions, perfect for intricate designs.

Rapid Prototyping Services

Quickly transform ideas into prototypes using CNC milled molds, ensuring a seamless transition from concept to production. This service is efficient and cost-effective for complex projects.

Commitment to Quality and Customer Satisfaction

Our services emphasize quality, precision, and customer satisfaction, offering tailored solutions to meet specific requirements. We are dedicated to providing reliable, high-performance products that exceed expectations.

Contact us

Compression molding products offers a sustainable, precise, and versatile solution for various industries. Our expertise in rapid prototyping and advanced materials ensures we deliver innovative and reliable products. Contact us today to explore how we can bring your vision to life with our compression molding services.