Custom Silicone Product Manufacturing

On demand From Concept to Completion: Your Custom Silicone Manufacturing Partner

☆☆☆☆☆ See the Results of Two Decades of In-House Production

Custom silicone manufacturer quality assurance

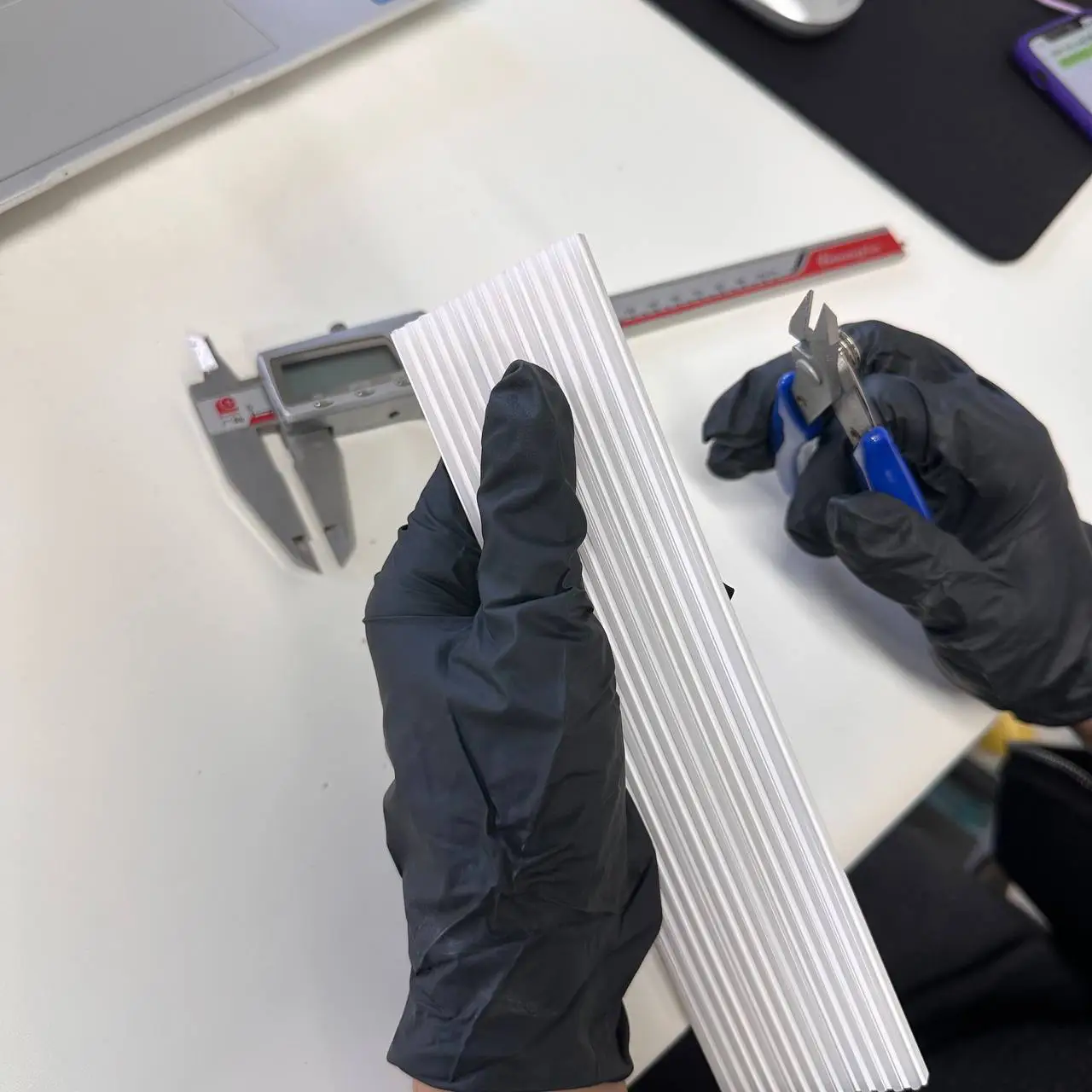

- Achieve tolerances ± 0.3

- Robust documentation and process validation

- High-quality base materials from reputable suppliers

- Material traceability

- Dedicated customer service team

- Technical expertise for product development

- Full support from sketch to production

- Regular production schedules

- On-time delivery

Commitment to Quality

Customized Services

Client Centric Approach

Scalable and Supportive

Our comprehensive and customizable silicone manufacturing process

1. Design for Manufacturing (DFM)

2. Material Selection

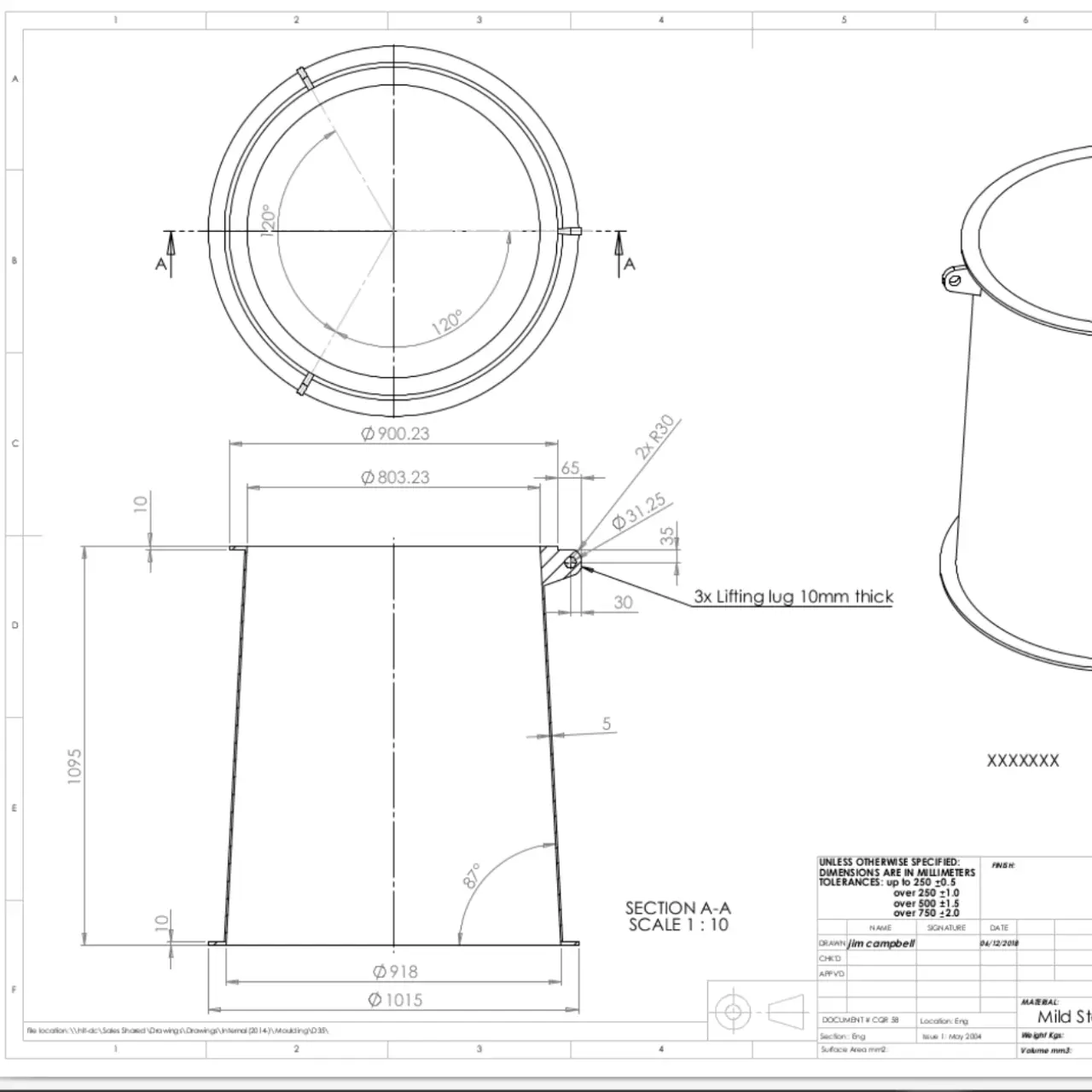

3. Tooling. Mold Machining

4. Prototyping

5. Curing

6. Finishing and Post-Processing

7. Quality Control Testing

8. Packaging

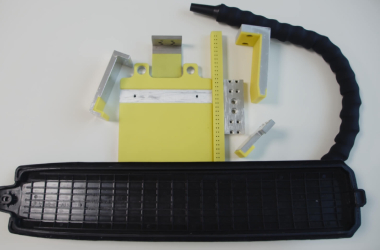

Comprehensive and customized silicone manufacturing methods

Silicone compression molding

This process involves pushing silicone through a die to create long, continuous shapes like tubes, cords, or strips. After the silicone is extruded, it’s cured to maintain its shape. This process is often used in the manufacturing of seals, gaskets, and surgical tubing.

Silicone extrusion molding

This process involves pushing silicone through a die to create long, continuous shapes like tubes, cords, or strips. After the silicone is extruded, it’s cured to maintain its shape. This process is often used in the manufacturing of seals, gaskets, and surgical tubing.

CNC mold machining

Mold-making involves the use of CNC machines to create highly accurate molds for silicone parts. This is the initial step in manufacturing silicone products and enables the production of intricate 3D shapes with precision. Due to its effectiveness, this method is widely employed across various industries.

Key advantages of silicone solutions from Dabojin

- Engineering Support: Material selection, design optimization, testing.

- Innovative Silicone Mixes: Enhanced conductivity, resistance.

- Rapid Prototyping & 3D Printing: Complex designs, fast testing.

- Full Service: Manufacturing, packaging, assembly, delivery.

- Regulatory Knowledge: Standards compliance in medical and food industries.

- In-House Tool and Mold Production: Quality control, swift alterations.

- Supply Chain Management: Quality, cost-effectiveness, punctuality.

- After-Sales Support: Warranties, technical help, updates.

- International Standards Compliance: Recognized quality and safety.

- Custom Packaging & Branding: Marketing support for clients.

What Clients Say About Our Service

Alex.

I’ve been sourcing various silicone products for my aquarium business from Dabojin. After seeing their range and how they handle everything, I knew, this is the supplier I’ve been looking for.

Dabojin is My Go-To!

Bruno.

We’ve been working with Dabojin for more than three years, and honestly, they know their stuff when it comes to Product Manufacturing. They’ve been a huge help to our business.

Expertise, You Can Trust

Amelia.

I’ve been collaborating with Dabojin for years and have made several trips to their factory. It’s a partnership that has stood the test of time, and I couldn’t be more satisfied.

Long-Term Partnerships

Get Started with Dabojin: Request Your Custom Quote Today

Can Dabojin handle end-to-end solutions in Product Manufacturing?

Yes, we offer a comprehensive approach that covers everything from concept to completion. We guide you through prototype tooling, sample approvals, mass production, and quality assurance.

What sets your Product Manufacturing apart in terms of quality?

We are certified for ISO 9001, ISO 45001, and ISO 14001 quality management systems. Our products also adhere to FDA guidelines, making them food-grade and skin-safe. For a detailed insight into how these standards set us apart in product manufacturing, visit our dedicated page on ISO and FDA compliance.

Can you handle large-scale Silicone Product Manufacturing orders?

Yes, we are equipped for large-scale production across our 6 specialized product lines and 38 machines, with 7 various services.

How flexible are you with custom Silicone Product Manufacturing?

We offer a high degree of customization to meet your specific needs, whether it’s a unique silicone grade or a complex product design. We’re supplying custom silicone products to a variety of industries with unique needs.

How is intellectual property handled in your Silicone Product Manufacturing process?

We respect the confidentiality of your intellectual property and are open to signing NDAs for added security.

How is intellectual property handled in your Silicone Product Manufacturing process?

We respect the confidentiality of your intellectual property and are open to signing NDAs for added security.